Apr 19, 2022

Soft robotic origami crawlers

Posted by Saúl Morales Rodriguéz in categories: biotech/medical, robotics/AI

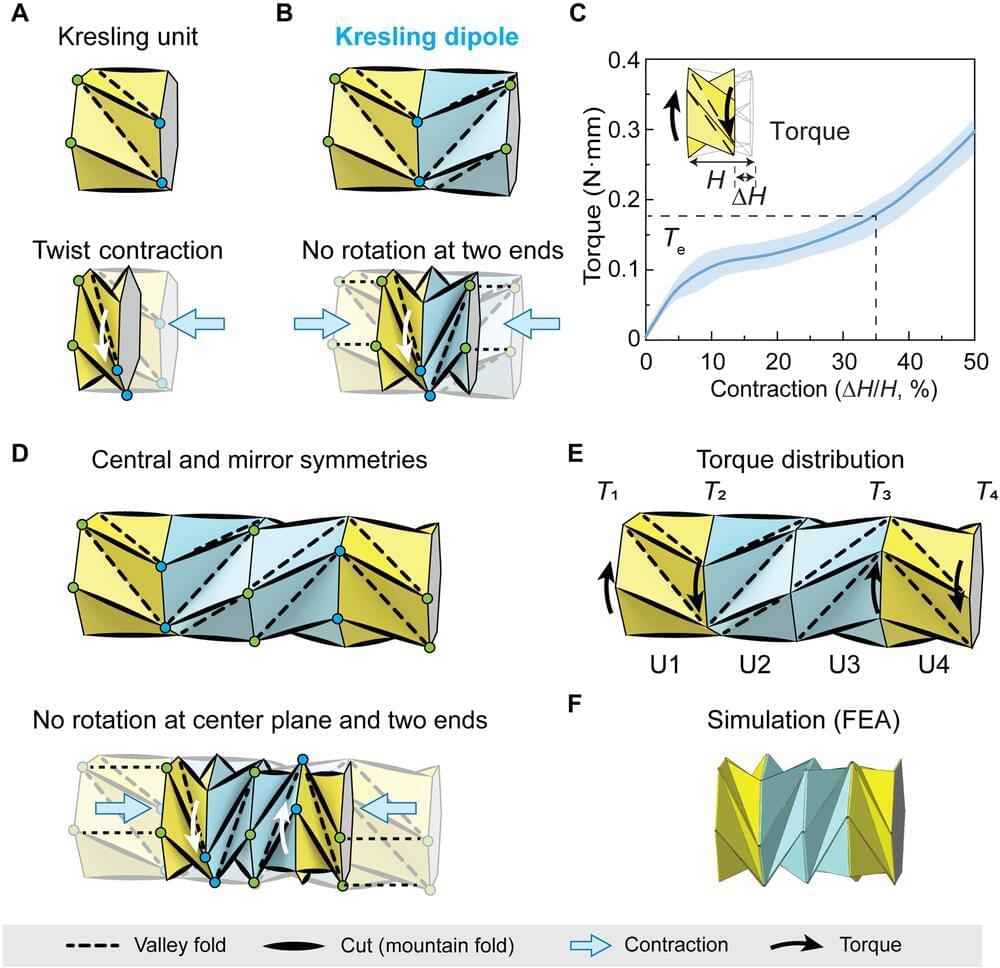

Materials scientists aim to develop biomimetic soft robotic crawlers including earthworm-like and inchworm-like crawlers to realize locomotion via in-plane and out-of-plane contractions for a variety of engineering applications. While such devices can show effective motion in confined spaces, it is challenging to miniaturize the concept due to complex and limited actuation. In a new report now published in Science Advances, Qiji Ze and a team of scientists in mechanical engineering and aerospace engineering at Stanford University and the Ohio State University, U.S., described a magnetically actuated, small-scale origami crawler exhibiting in-plane contraction. The team achieved contraction mechanisms via a four-unit Kresling origami assembly to facilitate the motion of an untethered robot with crawling or steering capacity. The crawler overcame large resistances in severely confined spaces due to its magnetically tunable structural stiffness and anisotropy. The setup provided a contraption for drug storage and release with potential to serve as a minimally invasive device in biomedicine.

Navigating complicated terrains

Bioinspired crawling motion shows adaptation to complicated terrains due to its soft deformable dimensions. Researchers aim to engineer crawling for a variety of applications in limited or confined environments, including extraterrestrial exploration, tube inspection, and gastrointestinal endoscopy. Origami provides an appropriate method to generate contraction relative to structural folding, which can be adapted to engineer robotic crawlers. The team described Kresling patterns; a specific type of bioinspired, origami pattern used to generate axial contraction under torque or compressive force, coupled with a twist from the relative rotation of the device units. Ze et al illustrated a magnetically actuated small-scale origami crawler to induce effective in-plane crawling motions. The scientists developed a four-unit Kresling assembly and verified torque distribution on the crawler using finite element analysis to induce motion.