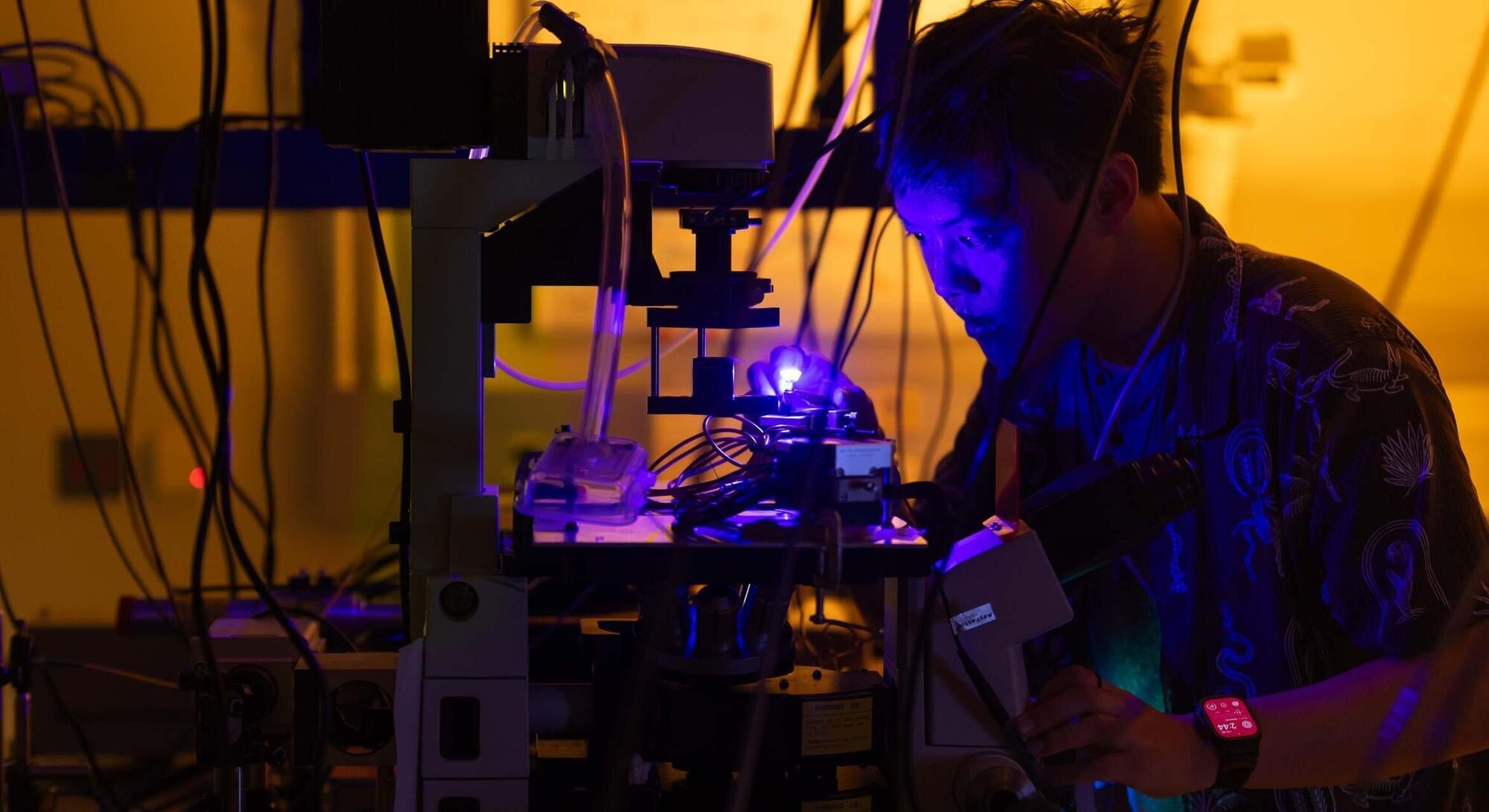

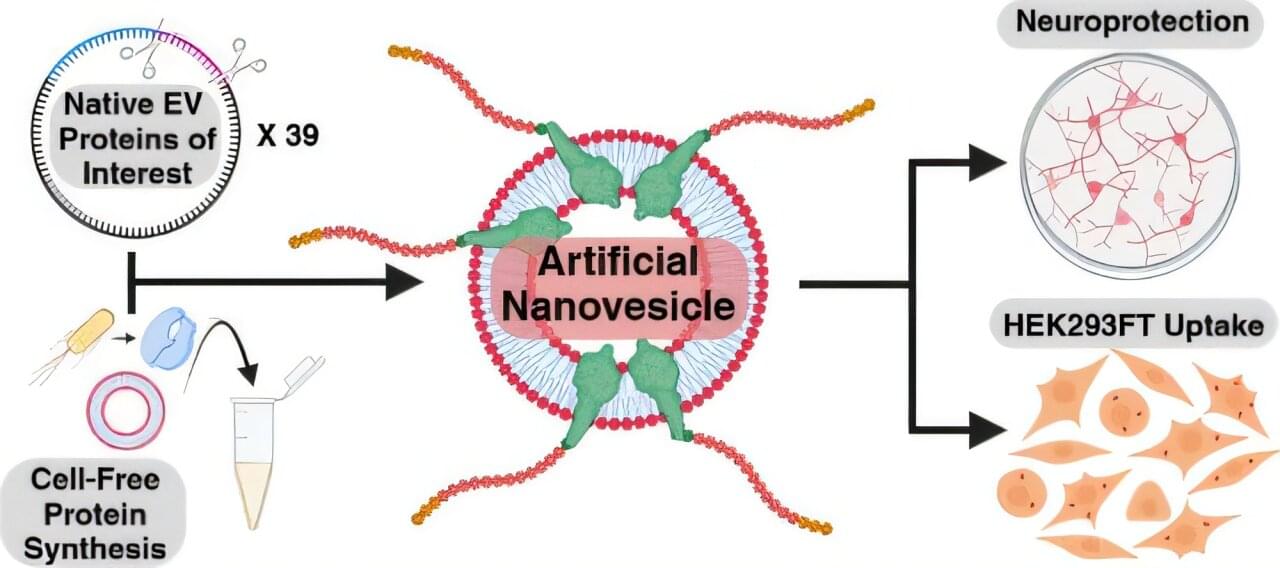

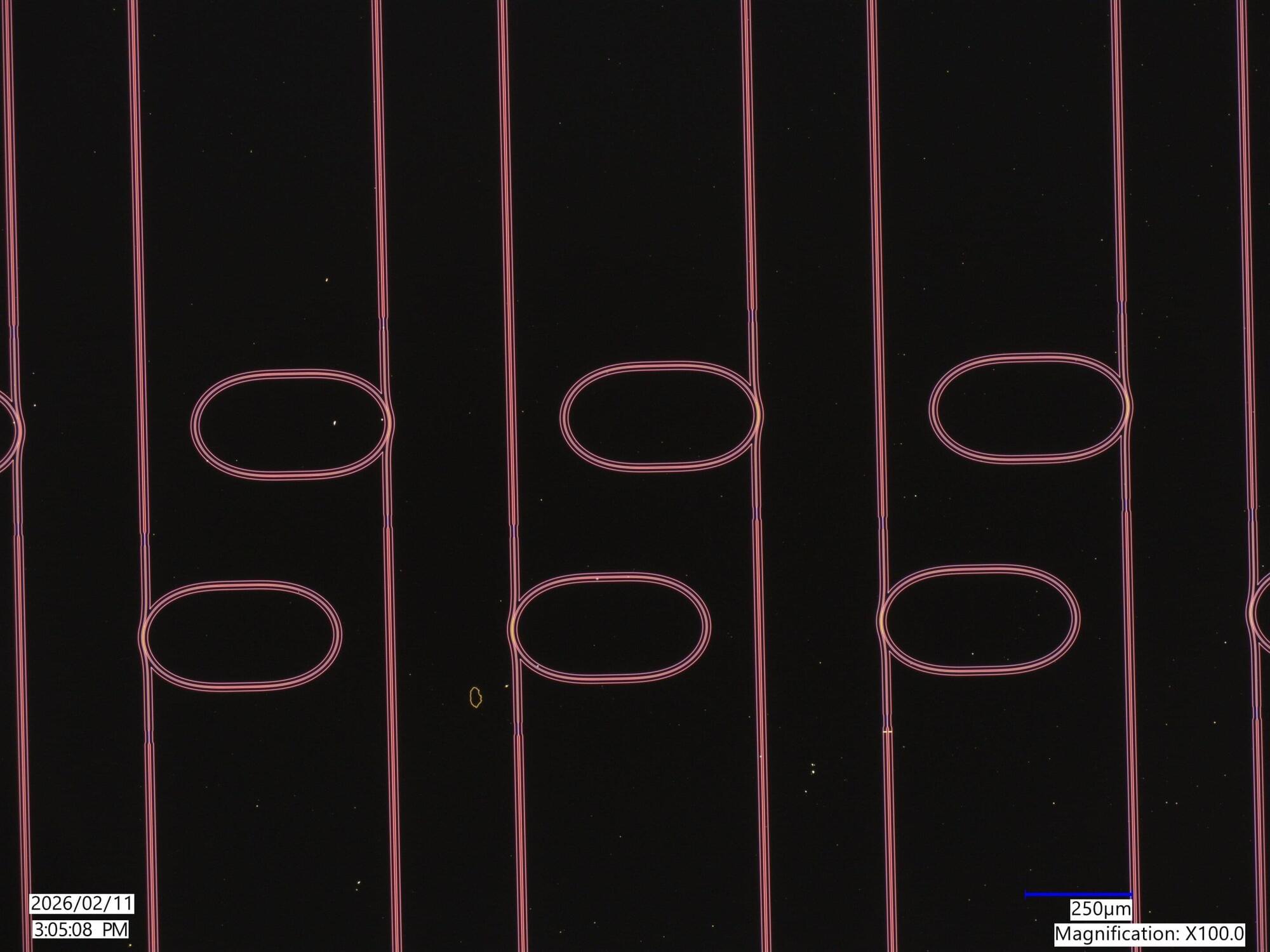

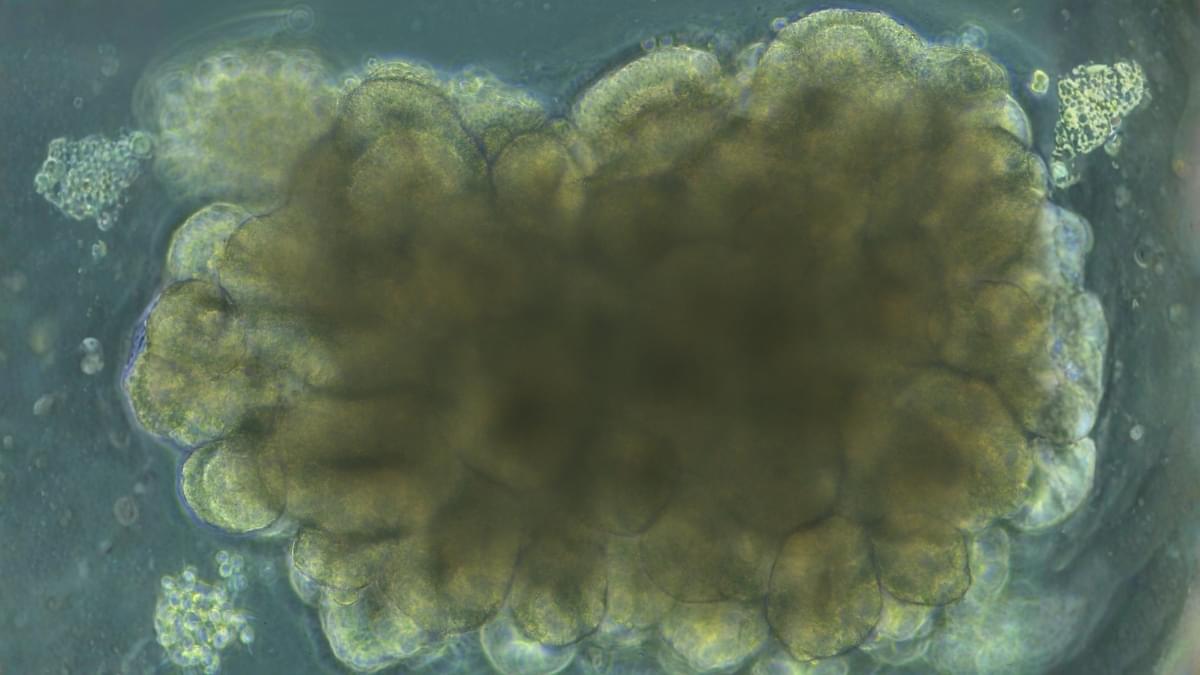

In this video we look into one of the developing areas of computing: wetware. Most specifically neuromorphic computing, a science which uses actual neurons on chips.

We talk to Cortical labs, the company that developed the pong-playing dish brain, and professor Thomas Hartung to understand what the benefits of this technology are.

🚀 Discover deep-dive engineering stories and breakthrough technologies on Interesting Engineering:

/ @interestingengineeringie.

🪖 Explore military innovation and defense technology on Military Mechanics:

/ @militarymechanicsie.

🔔 Subscribe to IE Brief for daily updates on the discoveries, technologies, and global developments shaping our world:

/ @ienews-brief.

🔬 Complex tech, simply explained. Discover how the world works with IE Explains: / @ie-explains