A new layered material enabled researchers to document a dramatic change in metallic electron behavior as the material goes from 3D to 2D.

Physicists in China have unveiled new clues to the origins of high-temperature superconductivity in an iron-based material just a single unit-cell thick. Led by Qi-Kun Xue and Lili Wang at Tsinghua University, the team’s experiments show that the effect emerges through a striking dichotomy between two atomic “sublattices” in the material—offering deeper insight into how superconductivity arises. Their results are published in Physical Review Letters.

When cooled below its critical temperature, a superconductor allows electrical currents to flow with virtually zero resistance. While most superconductors discovered so far have critical temperatures close to absolute zero, recent decades have seen the discovery of increasingly advanced materials that host the effect at ever higher temperatures, making them far easier to implement for practical applications.

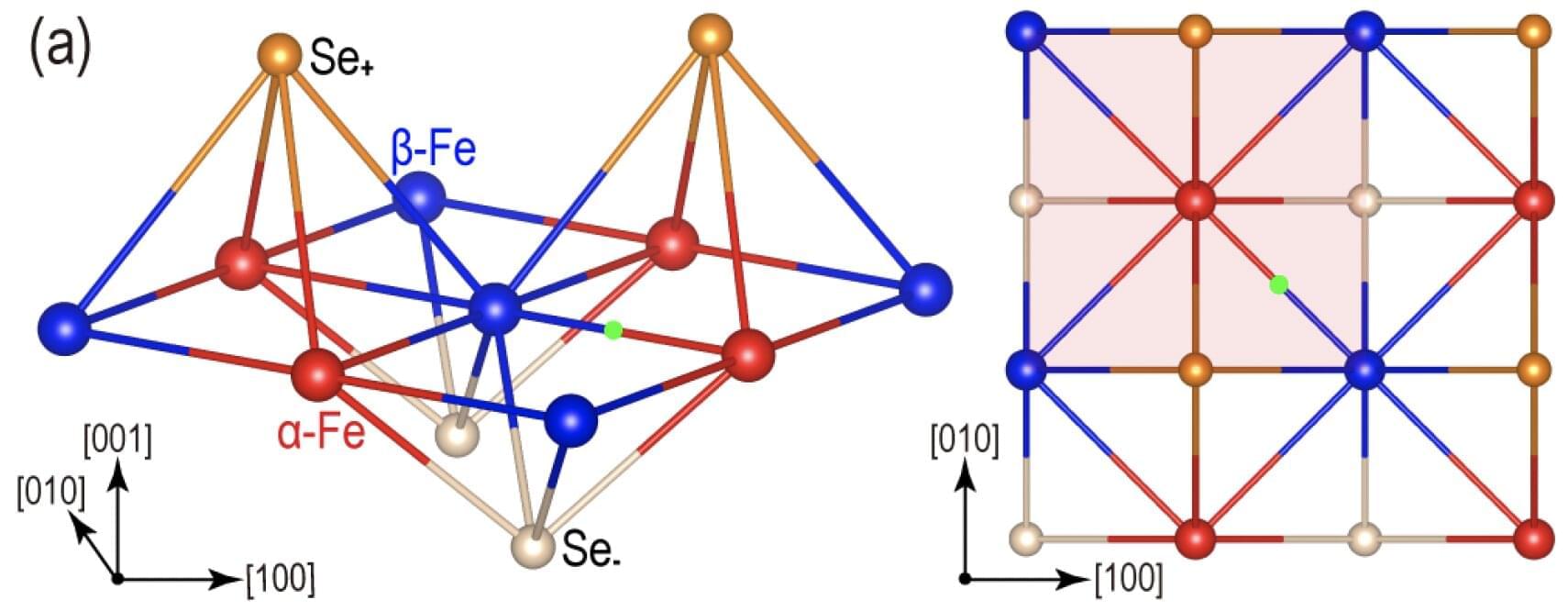

In 2012, superconductivity was discovered in a single-unit-cell-thick layer of iron selenide (FeSe), consisting of a Se–Fe–Se trilayer only 0.55 nm thick. However, it remained unclear how such a strong superconducting effect could emerge in such an ultrathin system.

The best candidate for next-generation magnetic devices—technology that can power, store, sense or transport information—may be, counterintuitively, antiferromagnets. Today, the most widely used magnetic materials are ferromagnets, which exhibit permanent magnetization and therefore strongly attract each other. Their opposite, called antiferromagnetic materials, exhibit no net magnetization at all. Despite a net zero magnetic field, they offer appealing properties that would solve the challenges of current magnetic technologies, like stray magnetic field generation or slow operation.

Now, a team led by researchers at Tohoku University has taken the first step toward developing antiferromagnetic technology. The researchers found, for the first time, that under a current, antiferromagnets can exhibit a phase of matter known as “liquid-crystal,” or nematic, that can be electrically detected. Their study is published in Nature Communications.

“The antiferromagnets we work with possess a fundamentally different symmetry from conventional ferromagnets, meaning that they are not simply an alternative material platform, but a new class of magnets expected to host entirely new electronic functionalities,” said corresponding author Hideaki Sakai.

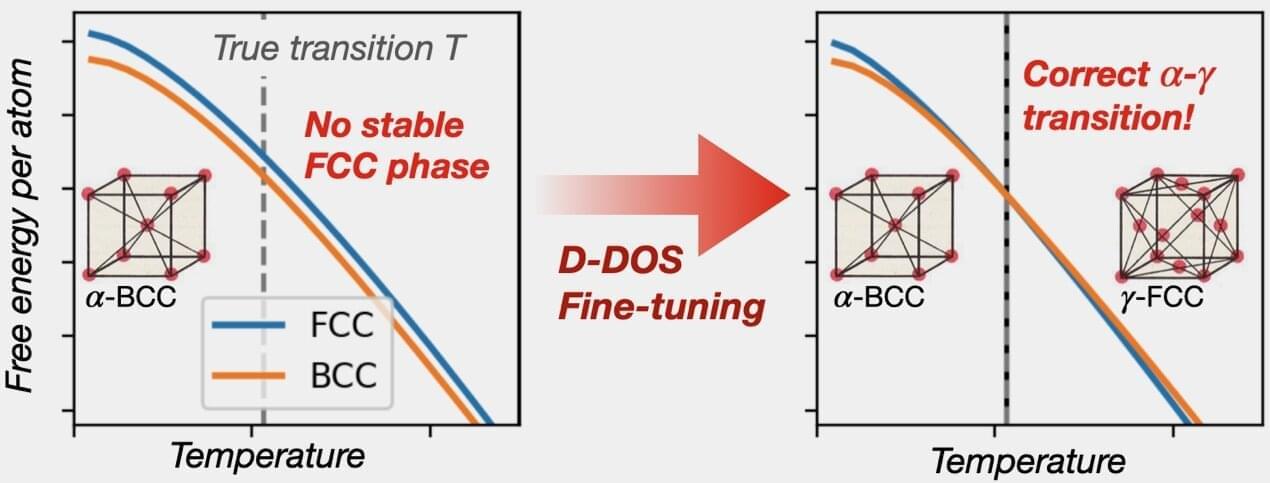

A new computational method allows modern atomic models to learn from experimental thermodynamic data, according to a University of Michigan Engineering and Université Paris-Saclay study published in Nature Communications. Leveraging a machine learning technique called score matching, the method expresses the thermodynamic free energy of atomic systems as a function of the underlying atomic interaction model, unlike standard schemes where the interaction model is fixed.

By returning thermodynamic predictions as functions rather than static numbers, the method, which is also over 10 times more efficient than previous approaches, can easily quantify and help accelerate computational materials discovery by opening up new inverse design capabilities. The method is called “descriptor density of states” and is abbreviated D-DOS.

“The D-DOS method provides a two-way connection between the latest generation of atomic simulations and the classical resource of phase diagrams, exposing these datasets to machine learning-driven computer models,” said Thomas Swinburne, an assistant professor of mechanical engineering at U-M and co-corresponding author of the study.

Wagner et al. show that dinoflagellate microalgae can biosynthesize crystalline materials which would otherwise be difficult to make synthetically. Scaling this up could eventually offer a new industrial approach for producing such materials. [ https://www.nature.com/articles/s41587-026-03006-6](https://www.nature.com/articles/s41587-026-03006-6)

Crystalline materials for optical applications are synthesized in living dinoflagellates.

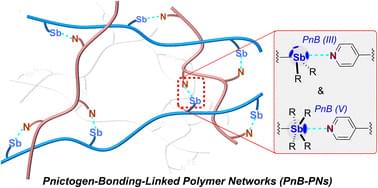

Herein, we introduce pnictogen bonding interaction into polymer networks for the design and modulation of dynamic macromolecular materials. Several types of polymeric pnictogen-bonding networks with graded interaction strengths were constructed to explore the structure–property relationship. Comprehensive investigations revealed that strengthening the pnictogen bonding significantly enhances the topological stability of the resulting materials. In contrast, analogous hydrogen-bonded networks did not exhibit comparable mechanical reinforcement. Moreover, the pnictogen-bonding networks endow the materials with tunable self-healing capability, allowing not only spontaneous healing at room temperature and thermally triggered healing on demand, but also effective healing in aqueous environments. This represents the first exploration of self-healing behavior driven by pnictogen bonding in polymeric materials. Mechanistic insights into the role of pnictogen bonding in polymer networks were elucidated through NMR titration of donor–acceptor polymer pairs, comparative self-assembly behavior, and cocrystal structures of small-molecule analogues. The incorporation of pnictogen bonding interaction into polymer networks provides a robust and versatile platform for engineering high-performance dynamic polymeric materials.

Conventional crystals are materials in which atoms arrange themselves in repeating spatial patterns. Time crystals, on the other hand, are phases of matter characterized by repeating motions over time without constantly heating up, breaking a physical rule known as time-translation symmetry.

Researchers at East China Normal University and Shanghai Jiao Tong University recently predicted the formation of a new type of time crystal, dubbed a two-dimensional (2D) moiré time crystal. This crystal was theorized to emerge when periodic perturbations (i.e., regular, repeated disturbances) are applied to ultracold atoms held in a smooth, continuous trap, as opposed to an optical lattice trap. The paper is published in the journal Physical Review Letters.

“We were inspired by two exciting concepts in physics,” Keye Zhang, professor at East China Normal University and co-senior author of the paper, told Phys.org. “The first is the concept of ‘twistronics,’ where twisting atom-thin layers creates moiré patterns with exotic material properties. While the second is that of ‘time crystals’ (a new phase of matter with persistent rhythmic motion). We wondered: could we combine these ideas by treating time itself as a dimension that can be ‘twisted’?”

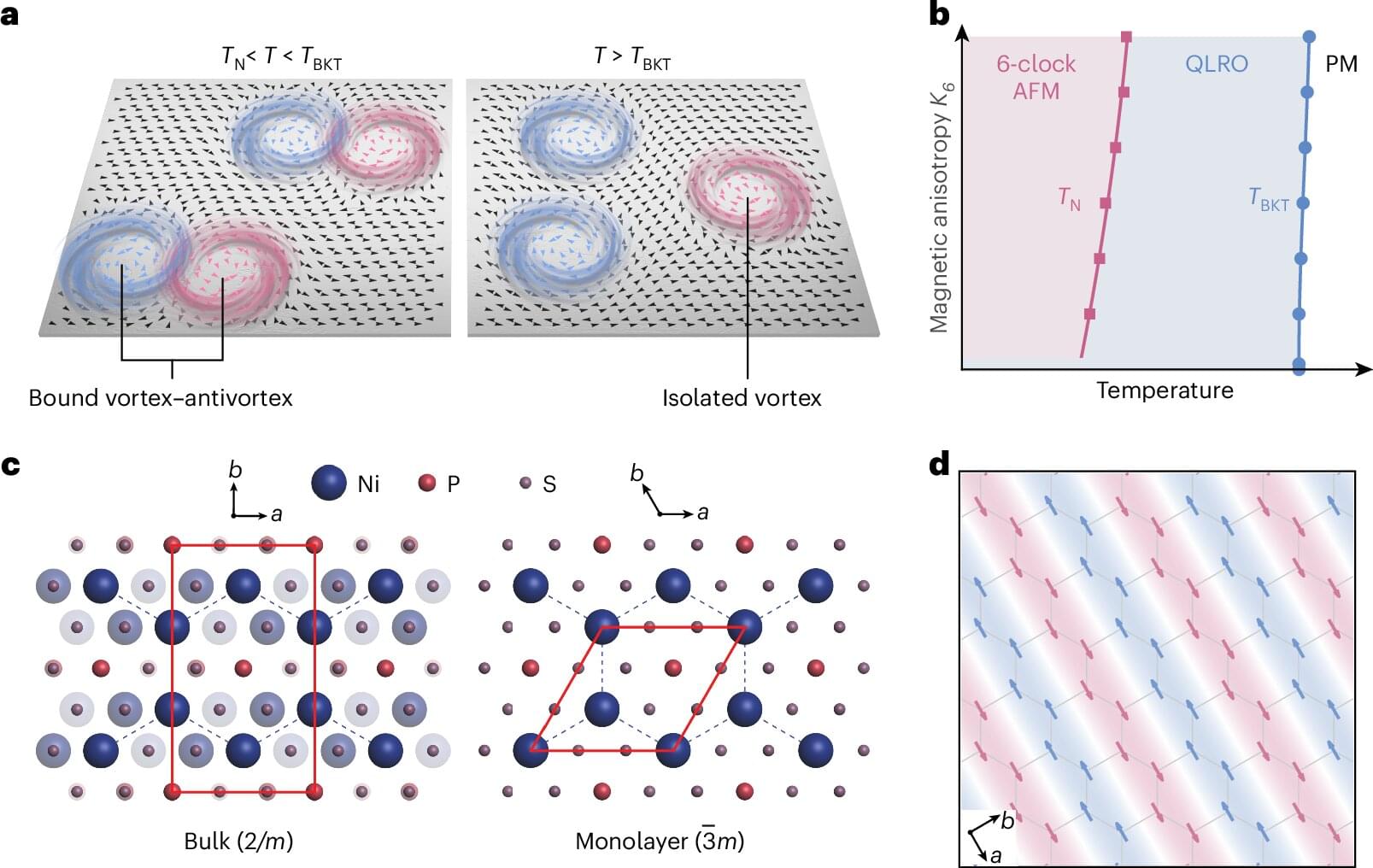

Strange things happen to materials when you peel them down, layer by layer, from thick chunks all the way to sheets just an atom thick. Reporting in the journal Nature Materials, a team led by physicists at The University of Texas at Austin has experimentally demonstrated a sequence of exotic magnetic phases in an ultrathin material that fully realizes, for the first time, a theoretical model of two-dimensional magnetism first proposed in the 1970s. The researchers say the advance might inspire new ultracompact technologies.

The sequence of exotic magnetic phases involves two key transitions that occur as certain materials cool down towards absolute zero. Both transitions have been observed experimentally on their own before, but never together in a complete sequence.

When the researchers cooled an atomically thin sheet of nickel phosphorus trisulfide (NiPS3) to temperatures between −150 and −130° C, the material entered the first special magnetic phase, called a Berezinskii–Kosterlitz–Thouless (BKT) phase. In this regime, the magnetic orientations associated with individual atoms in the material—known as magnetic moments—form swirling patterns called vortices. Pairs of these vortices wind in opposite directions, one clockwise and the other counterclockwise, and remain tightly bound together.

Some solid materials can cool down or heat up when pressure is applied or released. This behavior enables cooling and heating technologies that do not rely on climate-damaging refrigerant gases. In practice, however, a major obstacle remains: many materials behave differently during heating and cooling, which makes their response difficult to use reliably in real devices. In a study published in the journal Communications Materials, researchers investigate a solid material known for its exceptionally large cooling/heating response (thermal response) under pressure and ask a simple question: can this response be made more reliable? They show that a very small change in composition leads to a clear improvement and use neutron experiments to explain why this improvement occurs.

Recent decades have witnessed rapid advancements in high-intensity laser technology. The combination of laser irradiation and novel materials is opening exciting avenues for the design of functional materials and devices. Semiconductors are ideal platforms for generating laser-driven functionalities because they can exhibit novel features such as ultrafast optical transparency. This effect arises from electronic occupation redistribution driven by ultrafast excitation, which manifests as a phenomenon called transient Pauli blocking.

In a new development, a team of researchers in Japan, led by Professor Junjun Jia from the Global Center for Science and Engineering and the Graduate School of Advanced Science and Engineering at Waseda University, has examined the transient Pauli blocking effect in an InN film.

The study utilized pump-probe transient transmittance measurements with multicolor probe lasers, alongside first-principles electronic band-structure calculations. Their findings are published in Physical Review B.