At first glance, Rabih O. Al-Kaysi’s molecular motors look like the microscopic worms you’d see in a drop of pond water. But these wriggling ribbons are not alive; they’re devices made from crystallized molecules that perform coordinated movements when exposed to light. With continued development, Al-Kaysi and colleagues say, their tiny machines could be used by physicians as drug-delivery robots or engineered into arrays that direct the flow of water around submarines.

Get the latest international news and world events from around the world.

Tesla Rolls Out Full Self-Driving Beta v12.3 Update

The Tesla v12 software update is introducing what Musk has been calling “end-to-end neural nets”. The biggest difference with previous FSD updates is that the vehicle’s controls are now be handled by neural nets rather than being coded by programmers.

Method identified to double computer processing speeds

Hung-Wei Tseng, a UC Riverside associate professor of electrical and computer engineering, has laid out a paradigm shift in computer architecture to do just that in a recent paper titled, “Simultaneous and Heterogeneous Multithreading.”

Tseng explained that today’s computer devices increasingly have graphics processing units (GPUs), hardware accelerators for artificial intelligence (AI) and machine learning (ML), or digital signal processing units as essential components. These components process information separately, moving information from one processing unit to the next, which in effect creates a bottleneck.

In their paper, Tseng and UCR computer science graduate student Kuan-Chieh Hsu introduce what they call “simultaneous and heterogeneous multithreading” or SHMT. They describe their development of a proposed SHMT framework on an embedded system platform that simultaneously uses a multi-core ARM processor, an NVIDIA GPU, and a Tensor Processing Unit hardware accelerator.

Phase-change concrete melts snow and ice without salt or shovels

Incorporating a phase-change material into concrete, researchers have created a self-heating material that can melt snow and ice for up to 10 hours without using salt or shovels. The novel material could reduce the need for plowing and salting and help preserve the integrity of road surfaces.

According to the US Department of Transportation (DOT), more than 70% of roads are in snowy regions. Snow and ice accumulation reduces road friction and vehicle maneuverability, causing drivers to slow and increasing the risk of crashes. Snow-obstructed lanes and roads also reduce roadway capacity and increase travel time.

The DOT states that local and state agencies spend more than US$2.3 billion annually on snow and ice control operations, in addition to the millions spent repairing infrastructure damage caused by snow and ice. Salting is often used before a snow event to prevent icing, but the highly concentrated salt solution can deteriorate concrete or asphalt. In addition, when water seeps into the road and freezes, it expands, causing internal pressure and damaging the road.

Tesla Summon to get major improvements, Autopark gets a new name

Tesla Summon and Autopark are set to gain major improvements next month, according to company CEO Elon Musk. Autopark is also getting a new name, Musk said, as it appears to be on its way to being called “Banish.”

After Musk stated earlier this month that Tesla would have some “really cool stuff coming this month and next,” owners and fans of the company were left with their own imaginations to think of what could possibly be coming.

While many owners have wished for improvements of things like the Auto Wipers, Tesla has been working behind the scenes to improve some of its semi-autonomous driving features and certain parts of Enhanced Autopilot, including Summon and Autopark.

What makes Black Holes Grow and New Stars Form? Machine Learning helps Solve the Mystery

It takes more than a galaxy merger to make a black hole grow and new stars form: machine learning shows cold gas is needed too to initiate rapid growth — new research finds.

When they are active, supermassive black holes play a crucial role in the way galaxies evolve. Until now, growth was thought to be triggered by the violent collision of two galaxies followed by their merger, however new research led by the University of Bath suggests galaxy mergers alone are not enough to fuel a black hole — a reservoir of cold gas at the centre the host galaxy is needed too.

The new study, published this week in the journal Monthly Notices of the Royal Astronomical Society is believed to be the first to use machine learning to classify galaxy mergers with the specific aim of exploring the relationship between galaxy mergers, supermassive black-hole accretion and star formation. Until now, mergers were classified (often incorrectly) through human observation alone.

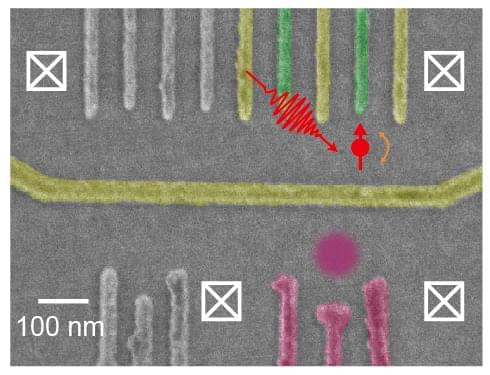

Shortcut to Success: Toward fast and robust Quantum Control through Accelerating Adiabatic Passage

Researchers at Osaka University’s Institute of Scientific and Industrial Research (SANKEN) used the shortcuts to the adiabaticity (STA) method to greatly speed-up the adiabatic evolution of spin qubits. The spin flip fidelity after pulse optimization can be as high as 97.8% in GaAs quantum dots. This work may be applicable to other adiabatic passage and will be useful for fast and high-fidelity quantum control.

A quantum computer uses the superposition of “0” and “1” states to perform information processing, which is completely different from classical computing, thus allowing for the solution of certain problems at a much faster rate.

High-fidelity quantum state operation in large enough programmable qubit spaces is required to achieve the “quantum advantage.” The conventional method for changing quantum states uses pulse control, which is sensitive to noises and control errors.