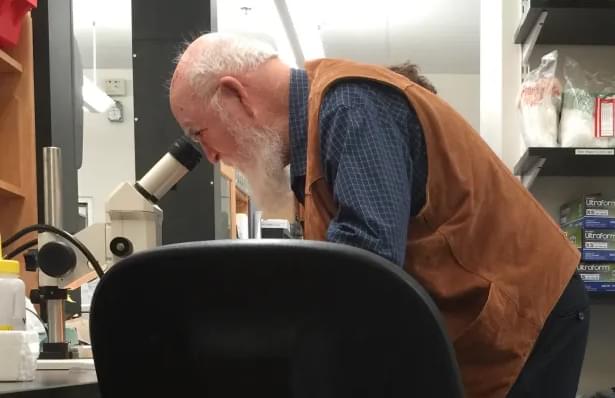

We lost a really great human today – philosopher Daniel C. Dennett.

Dan was a kind, honest, generous guy. He had a brilliant mind – insightful, critical, with an encyclopedic knowledge of pithy analogies and clinical examples (“intuition pumps” he called them), as well as who came up with them. And despite all of his experience and accomplishments, he always had a kind of childish excitement about new ideas, and new experiments. What he liked best was new insights, wild ideas, honest argument. I first heard the concept of “steel-manning” from him (opposite of “straw man” – putting forth the strongest, best version of an argument you want to critique). He was not interested in cheap wins or rhetorical bullying – he wanted to get to the best version of every story about nature and about ourselves.

I first came into contact with Dan through his books. As a teenager, Brainstorms, Elbow Room, and The Intentional Stance were a fantastic introduction to the most interesting questions, and ways of thinking about them. My dad and I would hit the bookstores every Saturday and there was no way a Dennett book would escape us if a new one came out. We had lots of great times discussing the topics in his books. I eventually was able to ask Dan to sign a few of them for dad, as birthday presents.