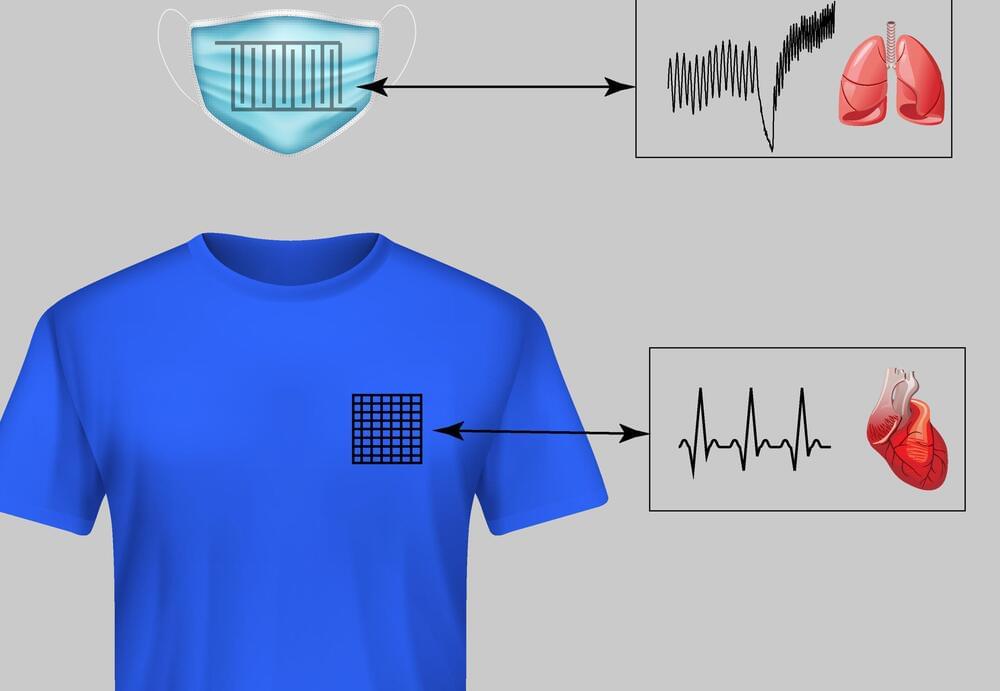

A new technology that incorporates flexible fiber sensors into shoes has been developed by the National Nanotechnology Research Center (UNAM) at Bilkent University and is able to identify a number of health issues, including Parkinson’s disease and gait disorders.

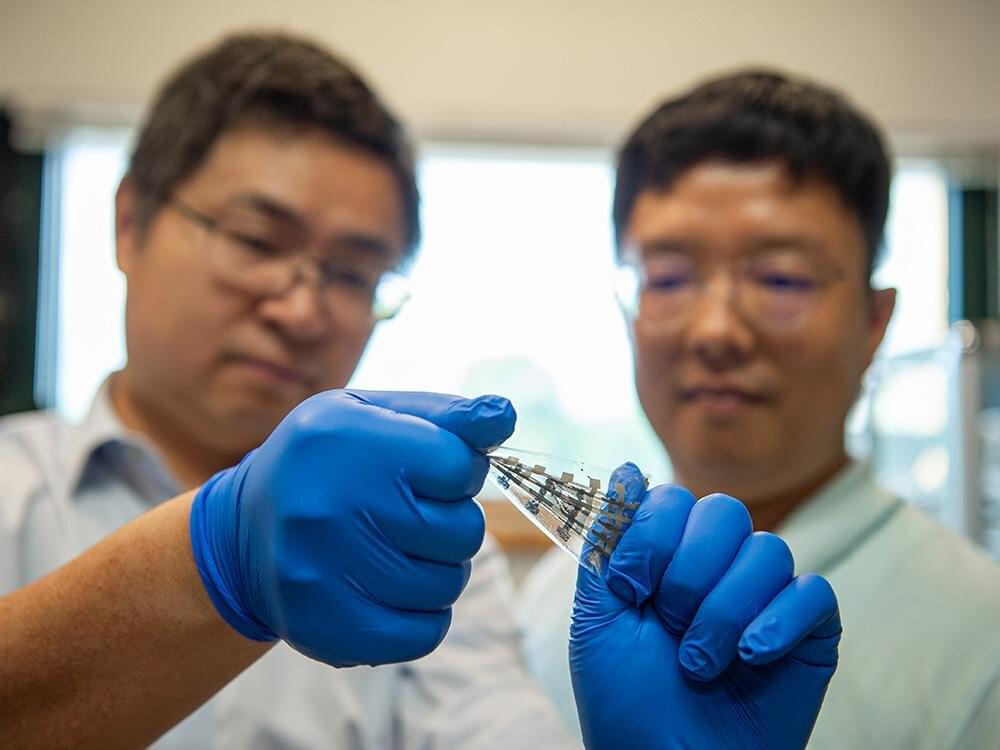

Project manager Mustafa Ordu, who specialized in the production and characterization of fiber cables that can generate electricity for wearable devices, explained that the technology developed at UNAM is loaded with smart sensors that can monitor body movements and determine issues and diseases, with the potential to diagnose many health problems.

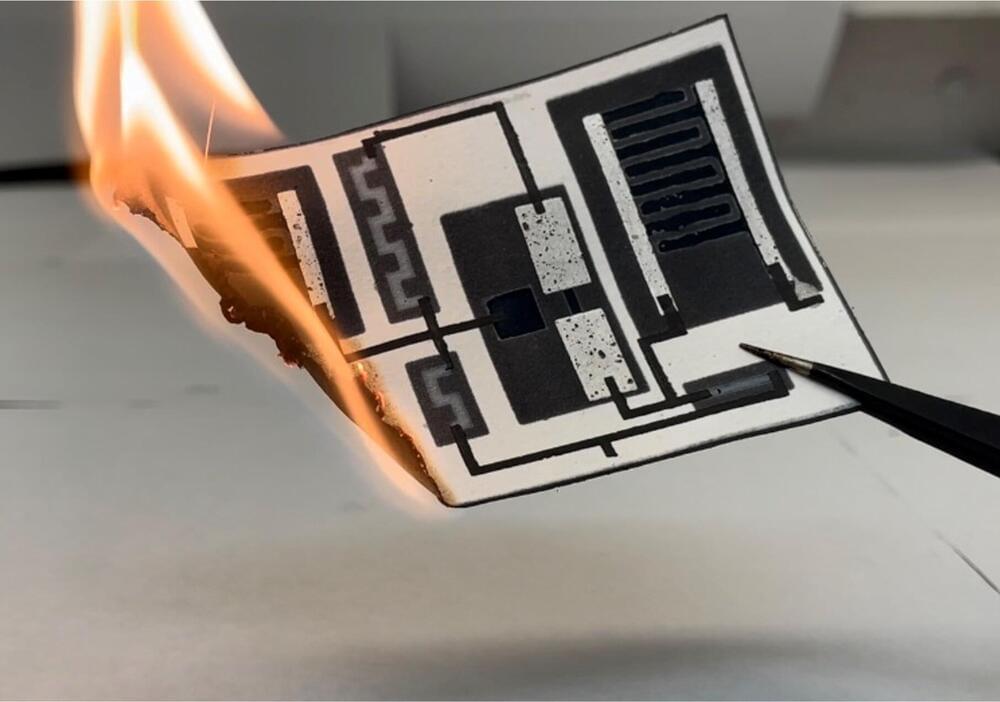

Further explaining the cutting-edge technology, he said that it can be woven into body wear or incorporated into footwear since by knitting these cables together like a type of threaded fabric, they can be incorporated into clothing as fibers. “This is what makes our team stand out among the existing laboratories in the world; we make smart sensors with flexible fiber and two-dimensional materials,” said Ordu.