A novel type of three-dimensional (3D) polar topological structure, termed the “polar chiral bobber,” has been discovered in ferroelectric oxide thin films, demonstrating promising potential for high-density multistate non-volatile memory and logic devices. The result was achieved by a collaborative research team from the Institute of Metal Research (IMR) of the Chinese Academy of Sciences, the Songshan Lake Materials Laboratory, and other institutions. The findings were published in Advanced Materials on January 30.

Topological polar textures in ferroelectrics, such as flux-closures, vortices, skyrmions, merons, Bloch points, and high-order radial vortices discovered in recent years, have attracted wide interest for future electronic applications. However, most known polar states possess limited configurational degrees of freedom, constraining their potential for multilevel data storage.

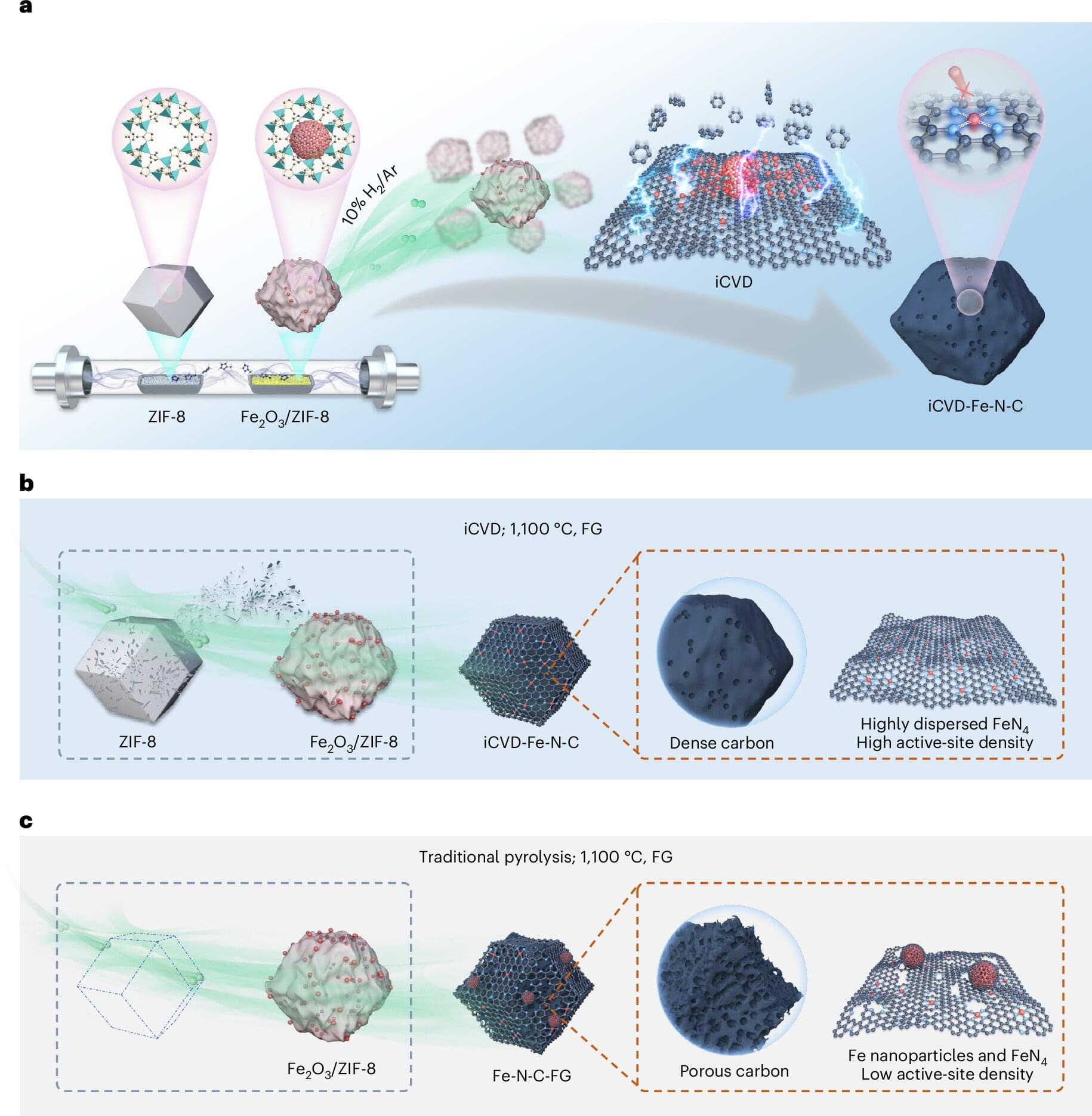

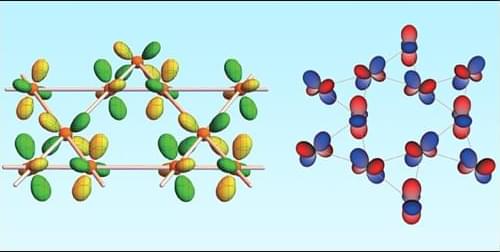

In this study, the researchers used phase-field simulations and aberration-corrected transmission electron microscopy to predict and experimentally confirm the existence of polar chiral bobbers in (111)-oriented ultrathin PbTiO₃ ferroelectric films. This 3D topological structure is characterized by a nanoscale domain with out-of-plane polarization opposite to its surroundings, which starts from the film surface and terminates at a Bloch point inside the film.