A new type of energy storage system could revolutionise energy storage and drop the charging time of electric cars from hours to seconds.

In a new paper published today in the journal Nature Chemistry, chemists from the University of Glasgow discuss how they developed a flow battery system using a nano-molecule that can store electric power or hydrogen gas giving a new type of hybrid energy storage system that can be used as a flow battery or for hydrogen storage.

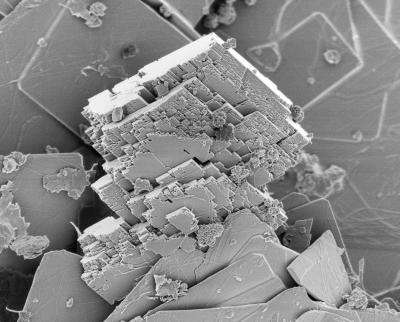

Their ‘hybrid-electric-hydrogen’ flow battery, based upon the design of a nanoscale battery molecule can store energy, releasing the power on demand as electric power or hydrogen gas that can be used a fuel. When a concentrated liquid containing the nano-molecules is made, the amount of energy it can store increases by almost 10 times. The energy can be released as either electricity or hydrogen gas meaning that the system could be used flexibly in situations that might need either a fuel or electric power.