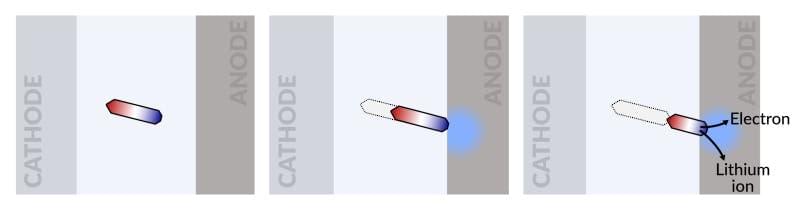

One of the key problems with lithium-ion batteries is that, over time, they do lose some of their battery life. This is why recycling them is so important. But what if there was a way to bring them back to life? And by this, I mean make them as good as new without recycling them. What if you could not only bring them back to life but extend the battery’s life by up to 30%?

Researchers at Stanford University along with the Department of Energy’s SLAC National Accelerator Laboratory may have done just that. No, this isn’t the beginning of a zombie horror apocalypse type of story, but it is a potentially revolutionary breakthrough.

Green Car Congress reports that the researchers might have found a way to bring rechargeable lithium batteries back to life with an increased boost to the range of battery life for both EVs and next-generation electronic devices. The study on the work has been published in Nature.