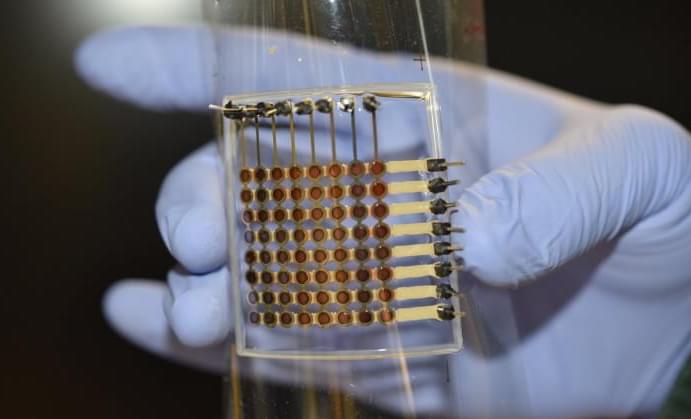

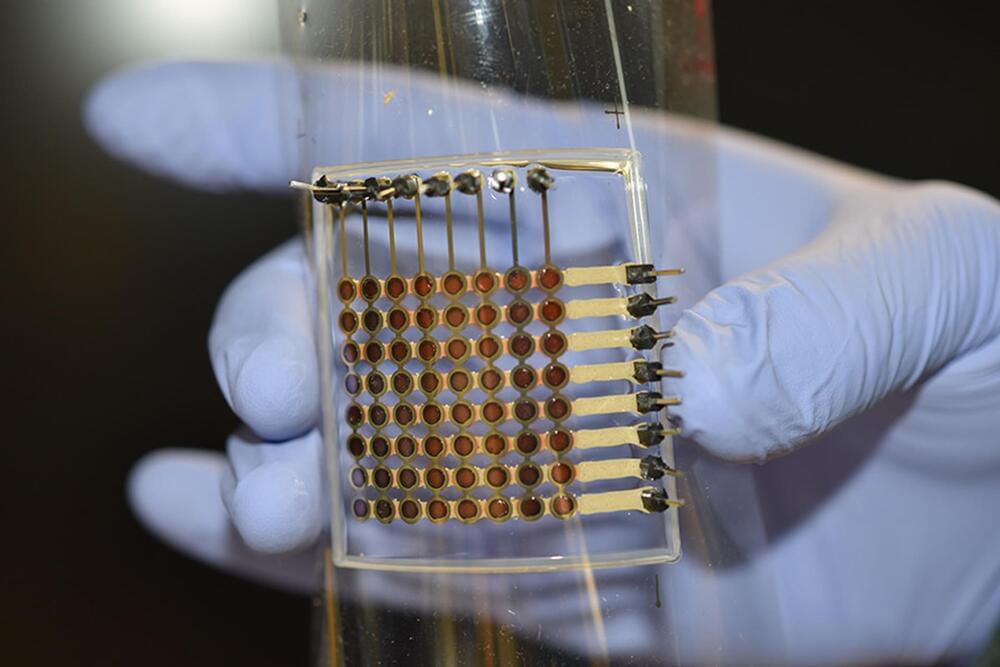

The researchers used extrusion printing to manufacture the electrodes, interconnects, encapsulation, and insulation. Active layers were then spray painted on at room temperature. All in all, six layers were 3D printed to build a flexible and fully functioning display.

“OLED displays are usually produced in big, expensive, ultra-clean fabrication facilities,” said Michael McAlpine, senior author of the team’s new study. “We wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.”