A new material can store energy from sunlight and convert it into hydrogen days later. The material, jointly developed by researchers from Ulm and Jena, can do this even in the dark. The process is reversible and can be reactivated several times using a pH switch. The results are published in the journal Nature Communications.

Green hydrogen is one of the most important pillars of the energy transition. It is produced from sunlight using photocatalytic processes. There are now a variety of technologies for converting and storing solar energy into chemical energy. But now, for the first time, a material that can store the energy from sunlight for several days and then release it in the form of hydrogen “at the push of a button” has been successfully developed.

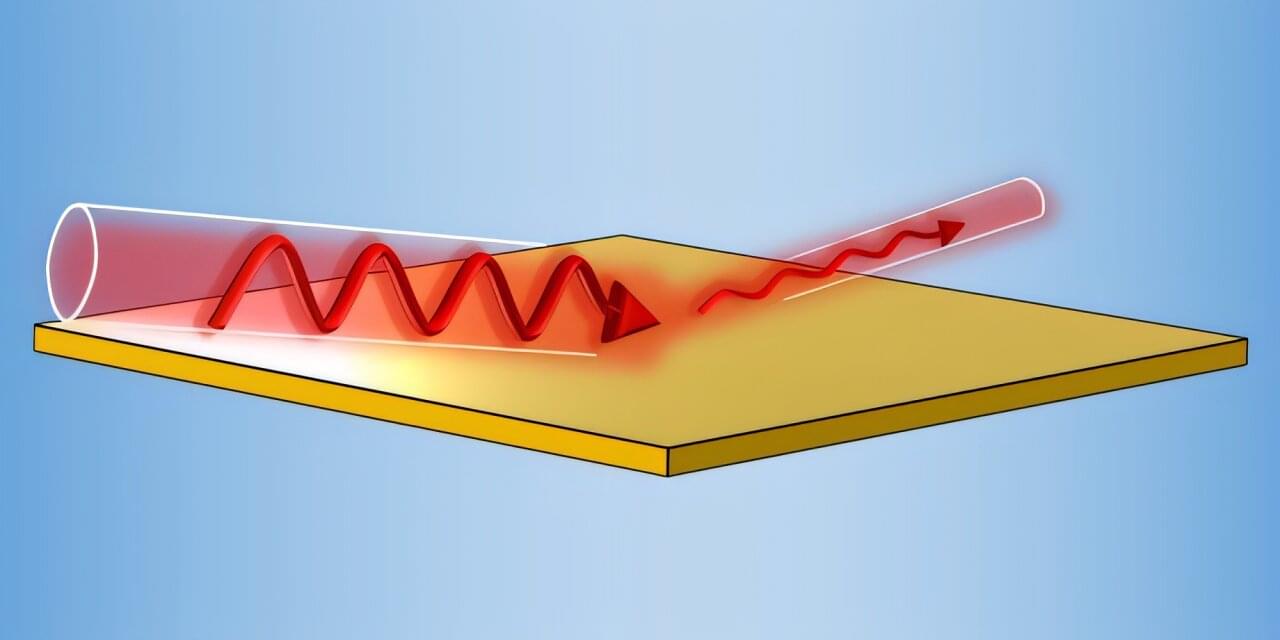

“You can think of it as a combination of a solar cell and a battery at the molecular level,” explains Professor Sven Rau, who heads the Institute of Inorganic Chemistry I at Ulm University.