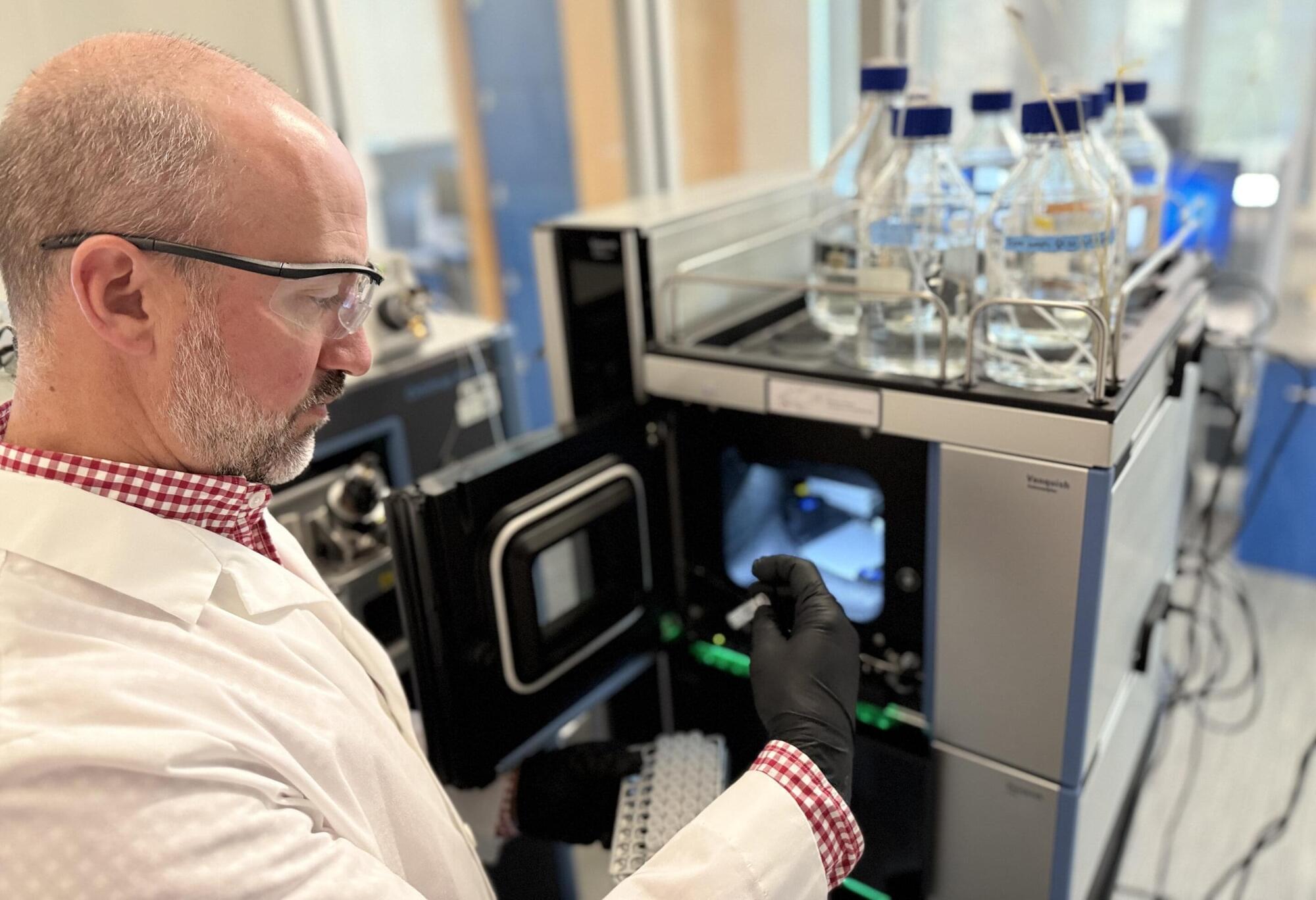

Earlier in 2025, Chinese solar manufacturer Longi announced it had built the world’s most efficient solar cell. The hybrid interdigitated back-contact (HIBC) cell achieved 27.81% efficiency, which was verified by Germany’s Institute for Solar Energy Research Hamelin (ISFH).

Now, in a paper published in the journal Nature, researchers are sharing the technical details of their breakthrough.

For solar technology to deliver on its promise, solar cells and panels must convert as much sunlight as possible into energy. Typically, standard cells achieve up to 26% efficiency, that is, they convert 26% of the sunlight hitting them into electrical energy.