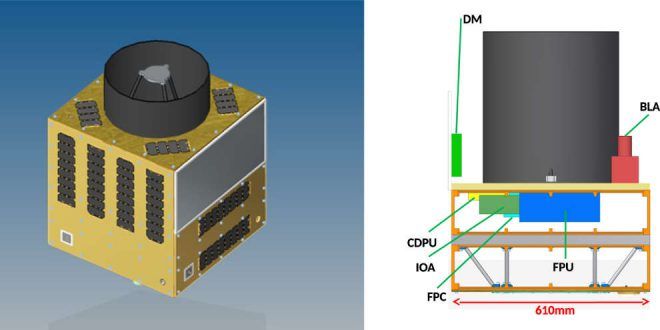

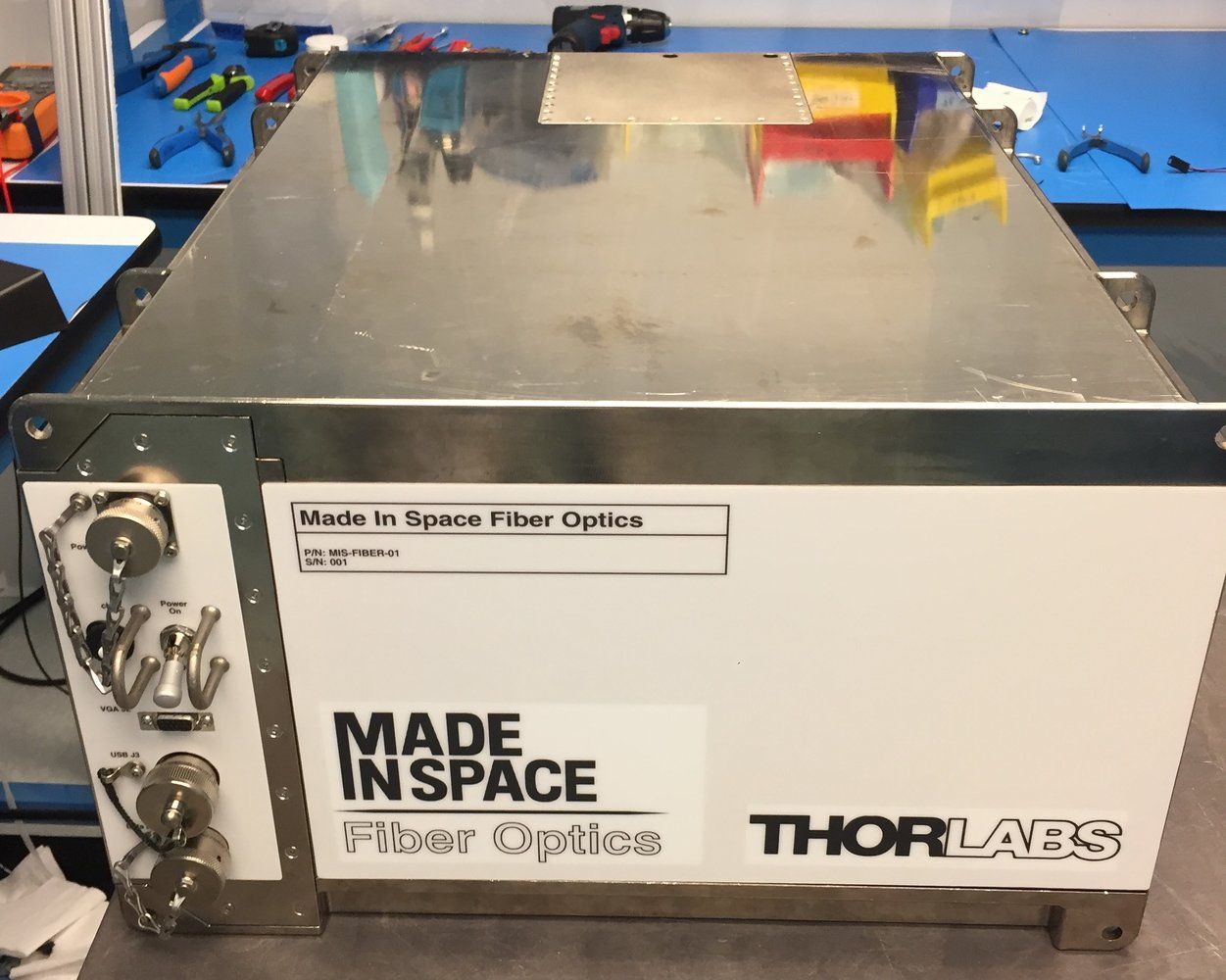

The Canadian Space Agency (CSA) has awarded $1.85M contract to the University of Waterloo for the Quantum Encryption and Science Satellite (QEYSSat) mission.

The QEYSSat mission was one of two projects cited in the 2017 budget when it was unveiled in March of this year. In April, the government sent Innovation Science and Economic Development (ISED) Minister Navdeep Bains to the CSA’s headquarters to formally announce the funding for the QEYSSat mission along with funding for a radar instrument that will be developed for a future orbiter mission to Mars and to announce the Canadian CubeSat Project. The $80.9M of funding would be over five years.

A short history of the QEYSSat mission.