Boston Dynamics’ Stretch can move 800 heavy boxes per hour.

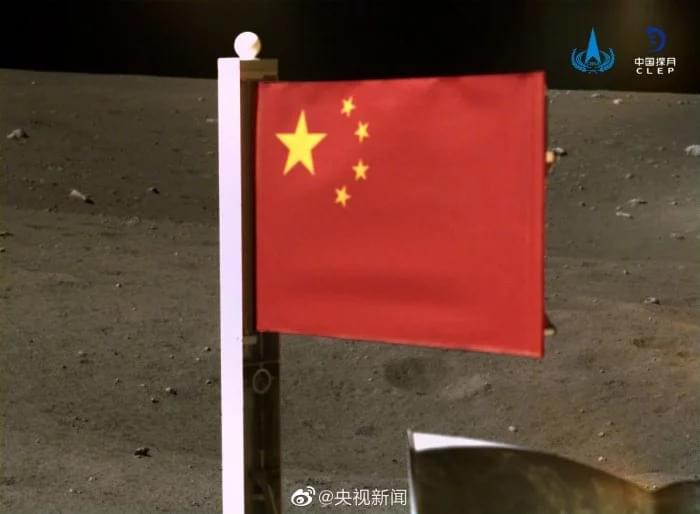

China has taken a giant leap forward in one of its most ambitious space programs. It has advanced its future lunar base plan by eight years.

China and Russia presented a detailed plan for a joint lunar base called the International Lunar Research Station, in June 2021, challenging a similar plan by the US.

On December 27, Chinese space officials revealed a revised completion date for the unmanned lunar base. It aims to set up the facility by around 2027, previously scheduled for 2035.

Kawasaki Heavy Industries announced the successful completion of proof-of-concept (PoC) testing for unmanned cargo transport by the cooperation of its K-RACER X1 unmanned vertical take-off and landing (VTOL) aircraft and delivery robot. The PoC testing was conducted with the aim of helping to solve societal issues such as labor shortages in the logistics industry.

In its Group Vision 2030, which describes the company’s future vision for 2030, Kawasaki specified three areas where it will focus its efforts: “A Safe and Secure Remotely-Connected Society,” “Near-Future Mobility” and “Energy and Environmental Solutions.” In the area of “Near-Future Mobility,” the company has been pursuing the development of unmanned VTOLs, delivery robots, and so on.

Kawasaki’s latest unmanned VTOL adopts improvements to an aircraft flight-tested in 2020. It is able to transport a 100-kilogram payload and is equipped with a delivery robot loading and unloading mechanism.

At this point, Scott-Morgan is almost completely “locked-in,” unable to move except for his eyes and a few facial muscles. His sense of smell and taste are gone, and he can’t breathe on his own, but his brilliant mind is fully intact.

Scott-Morgan now relies on a synthetic version of his biological voice and has had his face scanned to produce a 3D animated avatar, which he wears on a screen on his chest when speaking publicly. After a series of operations to extend his life, including a total laryngectomy, he uses technologies like GPT-2, OpenAI’s generative deep-learning model for text, pushing the boundaries of what it means to be human.

Alphabet’s self-driving car company Waymo is partnering with Chinese automaker Geely to create a fleet of all-electric, self-driving robotaxis.

The cars will be designed in Sweden (where Geely owns Swedish carmaker Volvo) and will be adapted from Geely’s all-electric five-door Zeekr. Waymo will then outfit the cars with the hardware and software necessary for autonomous driving. Waymo said in a blog post that it plans to deploy the vehicles in the US as part of its existing fleet of self-driving robotaxis some time “in the years to come.”

Concept images of finished vehicle shared by Waymo show a car that is designed specifically for autonomous ride-hailing trips. It has a flat floor, low step-in height, and B-pillarless design for easy entry and exit, as well as sliding doors, reclining seats, and plenty of headroom. Waymo says future models will have an interior without steering wheel or pedals — just a screen (presumably to let riders check on the progress of their journey).

Neuralink has received a whole range of reviews, with some scientists hailing it as the next big break and others claiming that the company is making promises it cannot deliver! Stick around for the full update and subscribe to Futurity.

#elonmusk #neuralink.

Here at Futurity, we scour the globe for all the latest tech releases, news, and info just so you don’t have to! Covering everything from cryptocurrency to robotics, small startups to multinational corporations like Tesla and Jeff Bezos to Elon Musk and everything in between!

We live in a very fast-changing world and quite an unpredictable one. In part, it is because we got lots of technological powers while our brain stays just the same as in pre-technological times. What do we teach children in this world? How can we help them to reflect on their thinking, get wiser in using the new technological powers, develop growth mindset and resilience, see the big picture and the interconnections within the complex systems (be that our body, ecological system, or the whole Universe)? We are trying to address these issues by teaching space science, AI and cognitive science, and existential risks and opportunities to pre-teens. In three years, the kids get an opportunity to talk to some of the most prominent thinkers in the field, reflect on deep questions, develop connections with specialists from multiple fields, from space law to ecology to virology, present their work at conferences. Check out our classes:

Art of Inquiry is an Online Science School for Young Explorers. We teach inquiry, thinking skills, and cutting-edge science. Our speakers and consultants are distinguished experts from academia, AI and space industry.

TuSimple has stated that its “Driver Out” program is the first vital step in scaling its autonomous trucking operations on the TuSimple Autonomous Freight Network (AFN).

A robust AFN is now one step closer, following a successful 80-mile, driverless run in Arizona last week.

TuSimple announced its successful driverless ride via a recent press release, along with YouTube footage of the entire one-hour twenty-minute drive.

Updating the goal of Chang’e 8 mission.

Chinese space authorities told state media South China Morning Post (SCMP) that the unmanned lunar station, jointly built with Russia, will be completed around 2027.

The new plan, which is eight years earlier than previously scheduled, will help China get ahead of the U.S. in the space race.

China’s Chang’e 8 moon landing mission was originally aimed to carry out scientific studies like 3D-printing lunar dust, but the Deputy Director of China National Space Administration (CNSA) Wu Yanhua announced that the new target of the administration is putting an unmanned research station on the lunar surface, which was previously scheduled for 2035.

Wu, while not disclosing the details behind the decision, underlined that the mission was to “build a solid foundation for the peaceful use of lunar resources”.

China’s lunar program has progressed steadily and at its own pace for years, with Chinese space authorities repeatedly claiming that the country was not interested in a space race like the one during the Cold War.

Full Story: