Researchers from the Institute of Metal Research (IMR) of the Chinese Academy of Sciences have developed an innovative flexible sensor that can simultaneously detect strain, strain rate, and temperature using a single active material layer, representing a significant advance in multimodal sensing technology.

The study, published in Nature Communications, addresses the longstanding challenge of conventional sensors requiring complex multilayer designs that integrate different materials for distinct sensing functions. These traditional approaches often involve complicated signal acquisition and external power supplies, limiting their reliability in continuous monitoring applications.

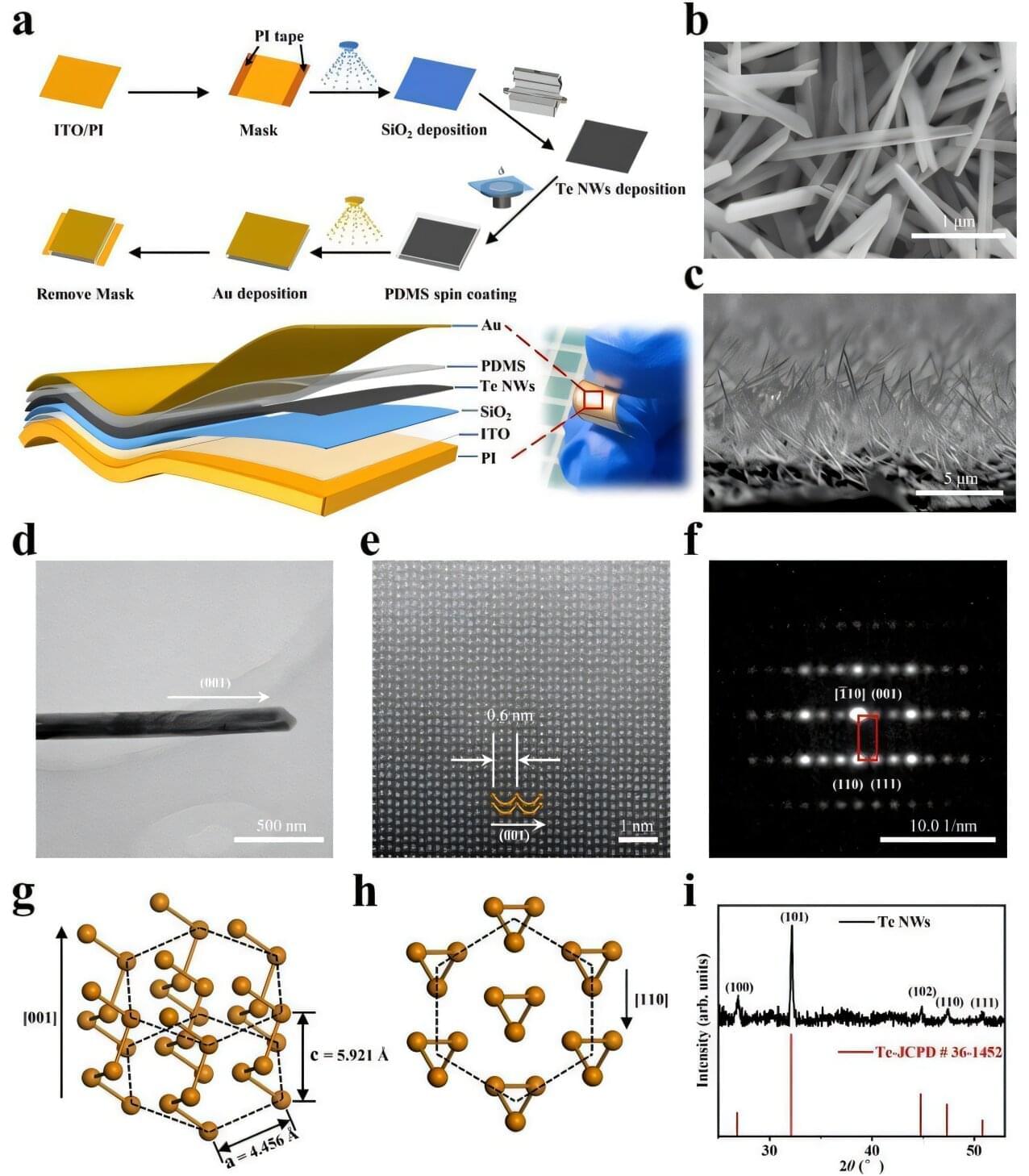

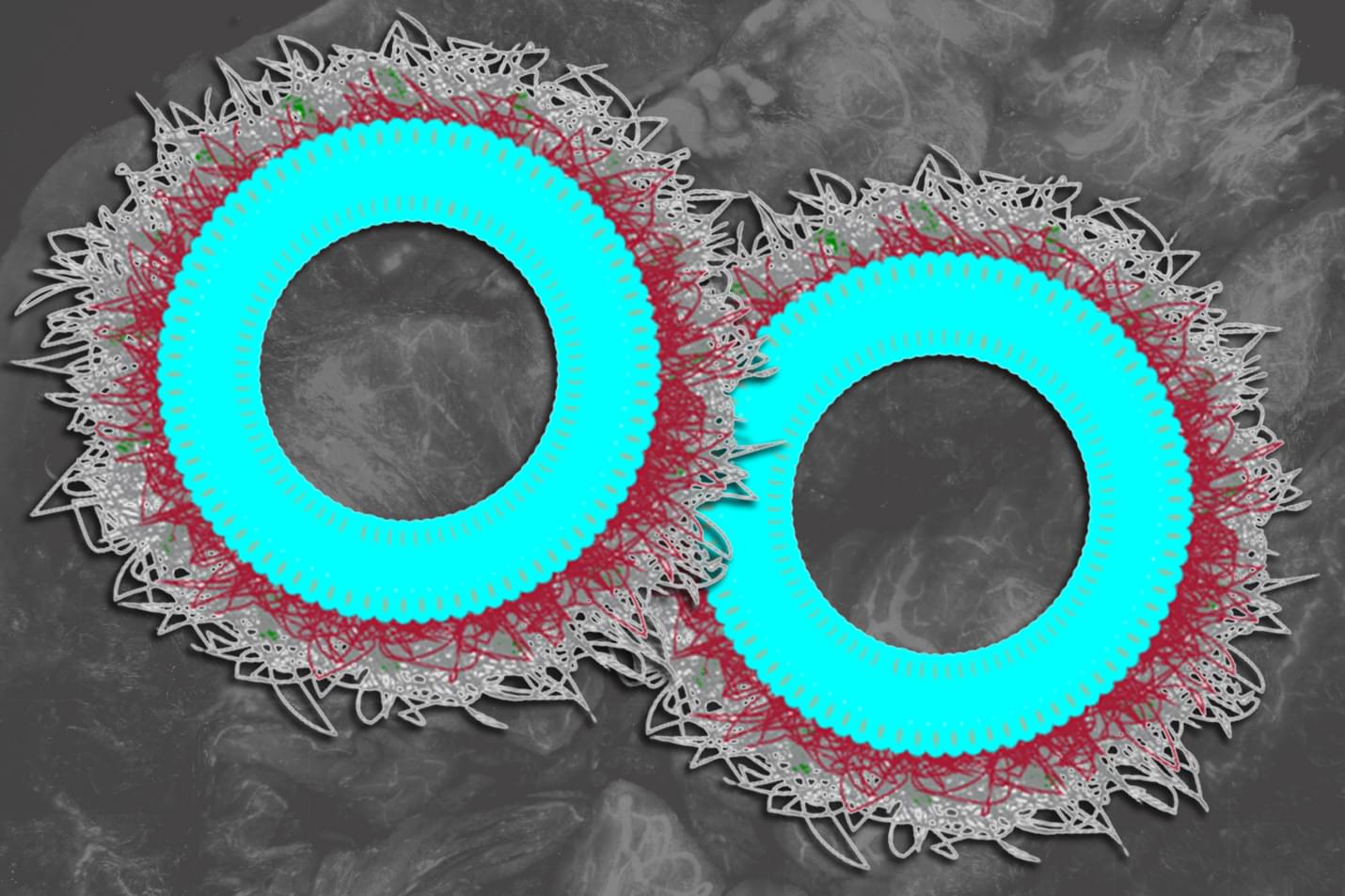

Led by Prof. Tai Kaiping, the researchers designed the sensor based on a specially designed network of tilted tellurium nanowires (Te-NWs). Through material and structural engineering, they overcame a fundamental limitation where thermoelectric and piezoelectric signals could not be collected in the same direction within conventional materials. In this unique architecture, both signals are simultaneously detected and output in the out-of-plane direction.