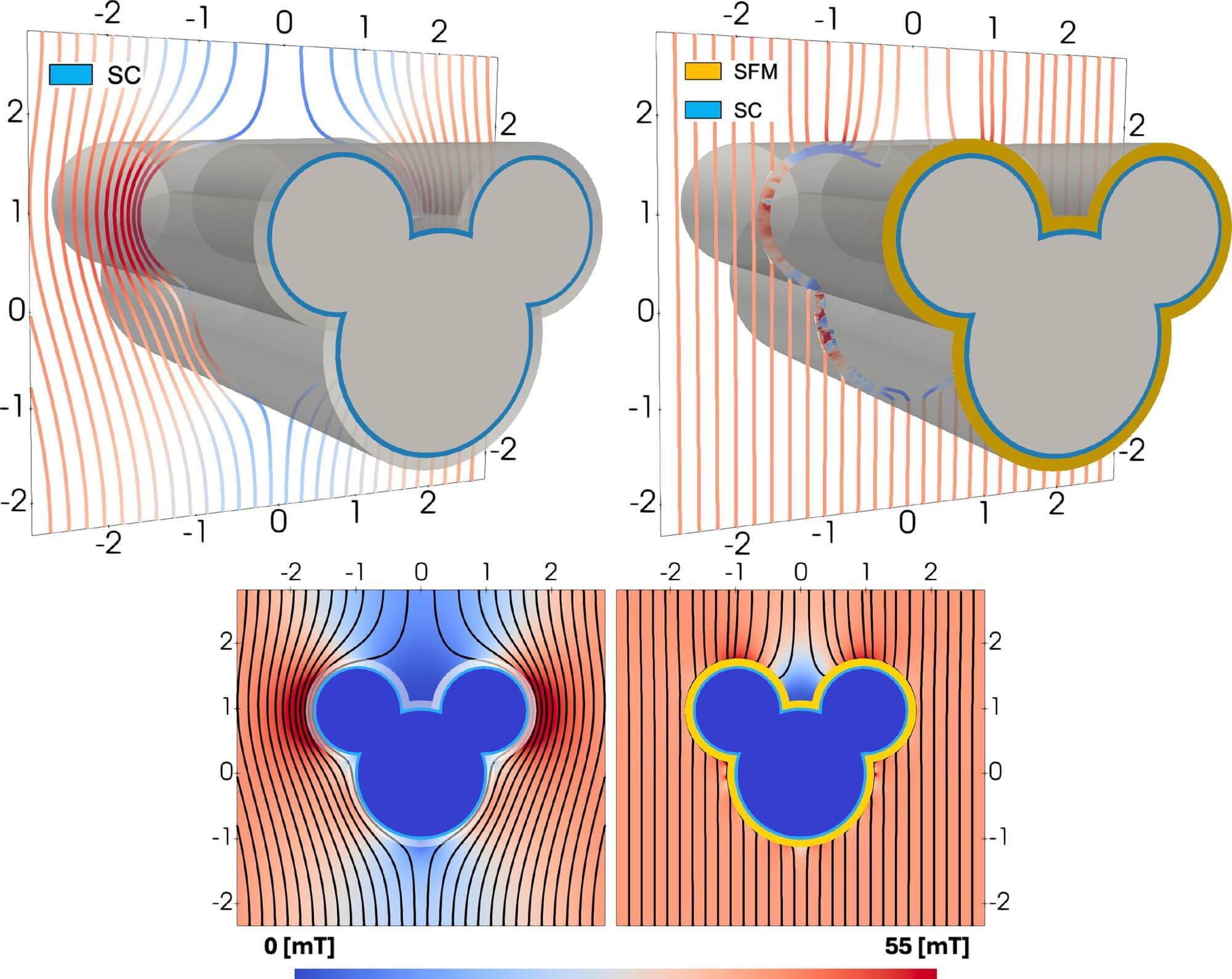

Superconductors are materials that can conduct electricity with zero resistance, usually only at very low temperatures. Most superconductors behave according to well-established rules, but strontium ruthenate, Sr₂RuO₄, has defied clear understanding since its superconducting properties were discovered in 1994. It is considered one of the cleanest and best-studied unconventional superconductors, yet scientists still debate the precise structure and symmetry of the electron pairing that gives rise to its remarkable properties.

One powerful way to identify the underlying superconducting state is to measure how the superconducting transition temperature, or Tc, changes under strain, since different superconducting states respond differently when a crystal is stretched, compressed, or twisted.

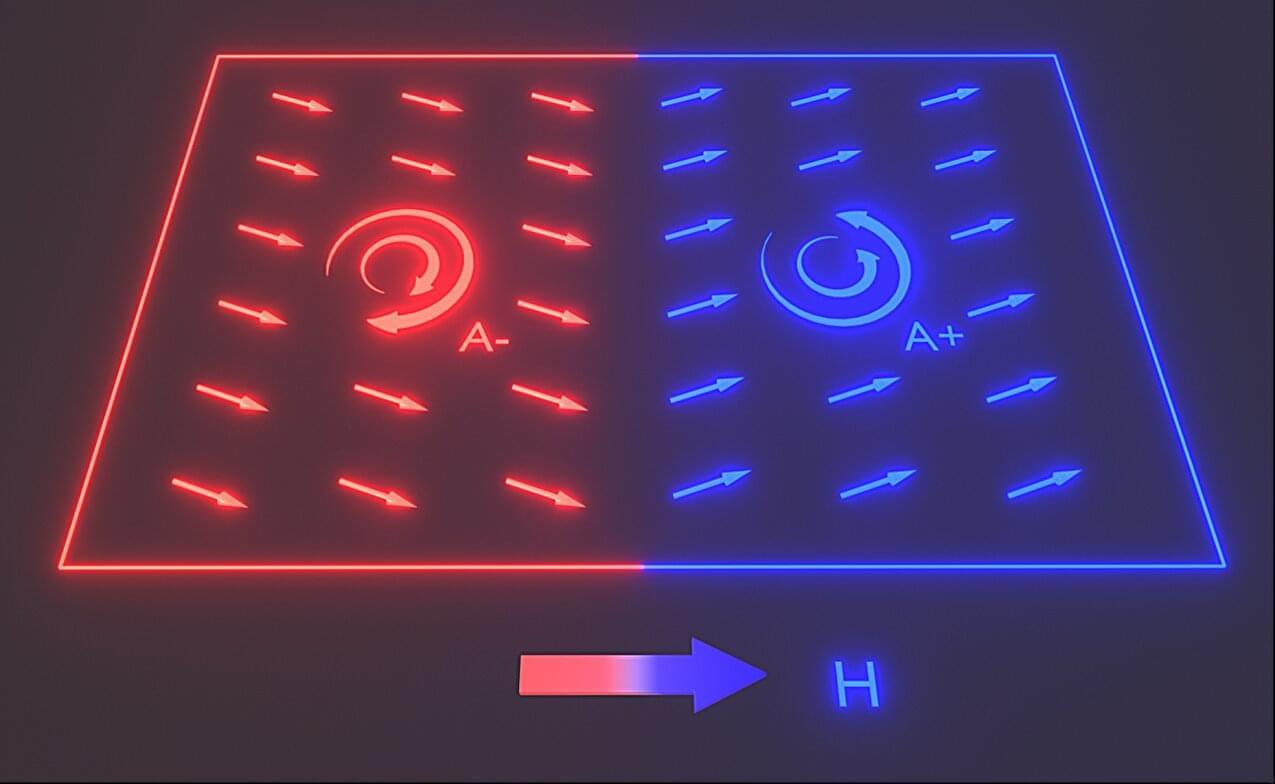

Many earlier experiments, especially ultrasound studies, suggested that Sr₂RuO₄ might host a two-component superconducting state, a more complex form of superconductivity that can support exotic behaviors such as internal magnetic fields or multiple coexisting superconducting domains. But a genuine two-component state is expected to respond strongly to shear strain.