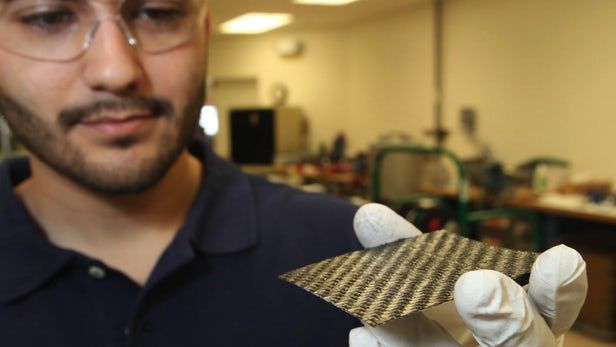

Real estate is a valuable commodity aboard a CubeSat, a compact satellite about the size of a shoebox, so the smaller each component can be made, the better. To that end, scientists at NASA’s Kennedy Space Center and the University of Miami are developing a thin, solid-state battery, which could not only save space for more important instruments aboard satellites, but also provide power on other planets, in cars or within the walls of a home.

At less than 3 mm (0.1 in) thick, the new batteries could be incorporated into the structure of pint-sized satellites, rather than taking up room in the area designated for research instruments. The batteries are made by sandwiching a solid-state battery layer between two layers of compressed carbon fiber.

“Creating a structural battery material could revolutionize the way NASA operates small payloads,” says senior principal investigator, Luke Roberson. “Rather than placing a battery in the experiment taking up 20 to 35 percent of the available volume, the battery now resides in the payload structure, thereby opening up additional free space for researchers to perform more science.”