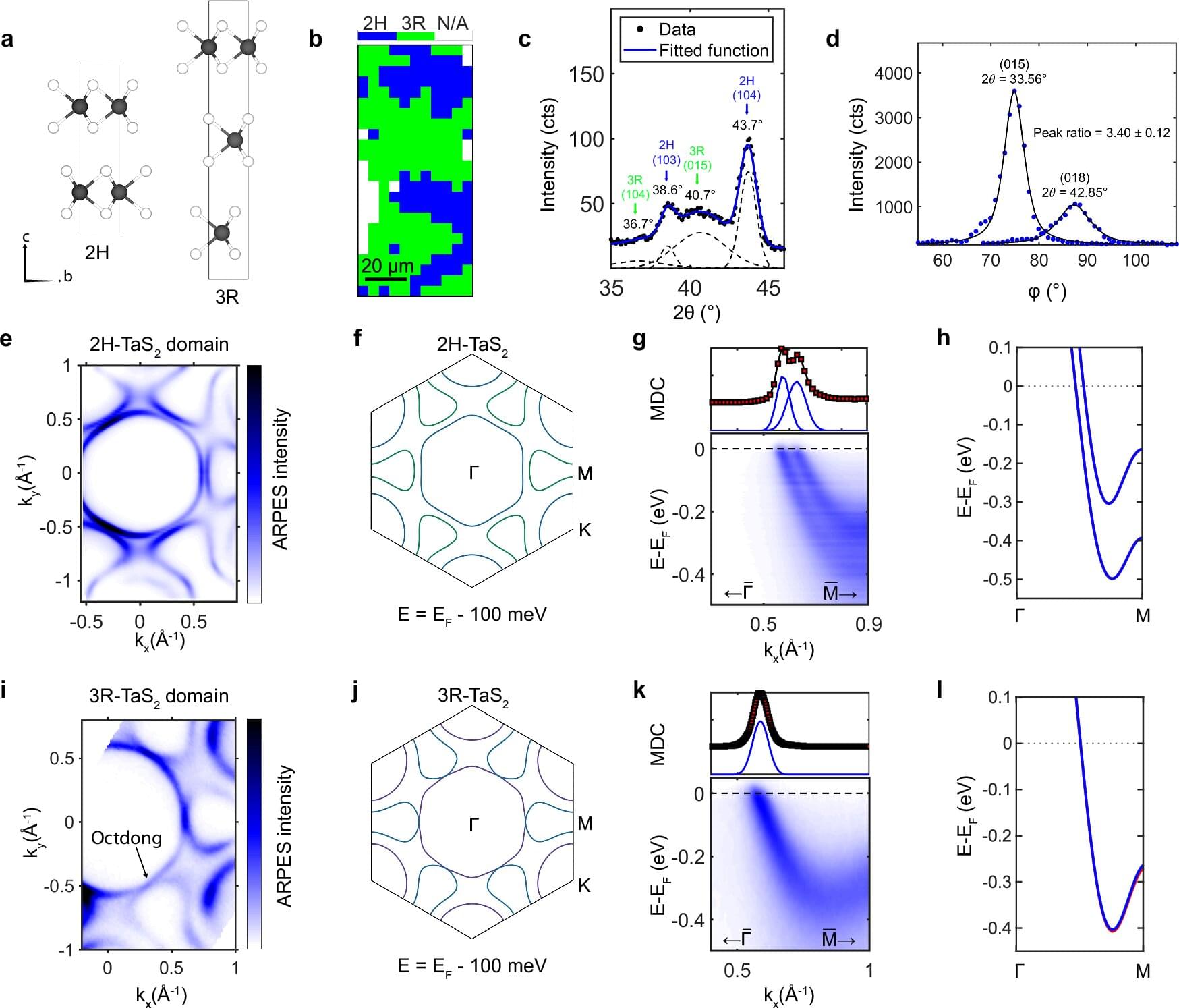

As the miniaturization of silicon-based semiconductor devices approaches fundamental physical limits, the electronics industry faces an urgent need for alternative materials that can deliver higher integration and lower power consumption. Two-dimensional (2D) semiconductors, which are only a single atom thick, have emerged as promising candidates due to their unique electronic and optical properties. However, despite intense research interest, controlling the growth of high-quality 2D semiconductor crystals has remained a major scientific and technological challenge.

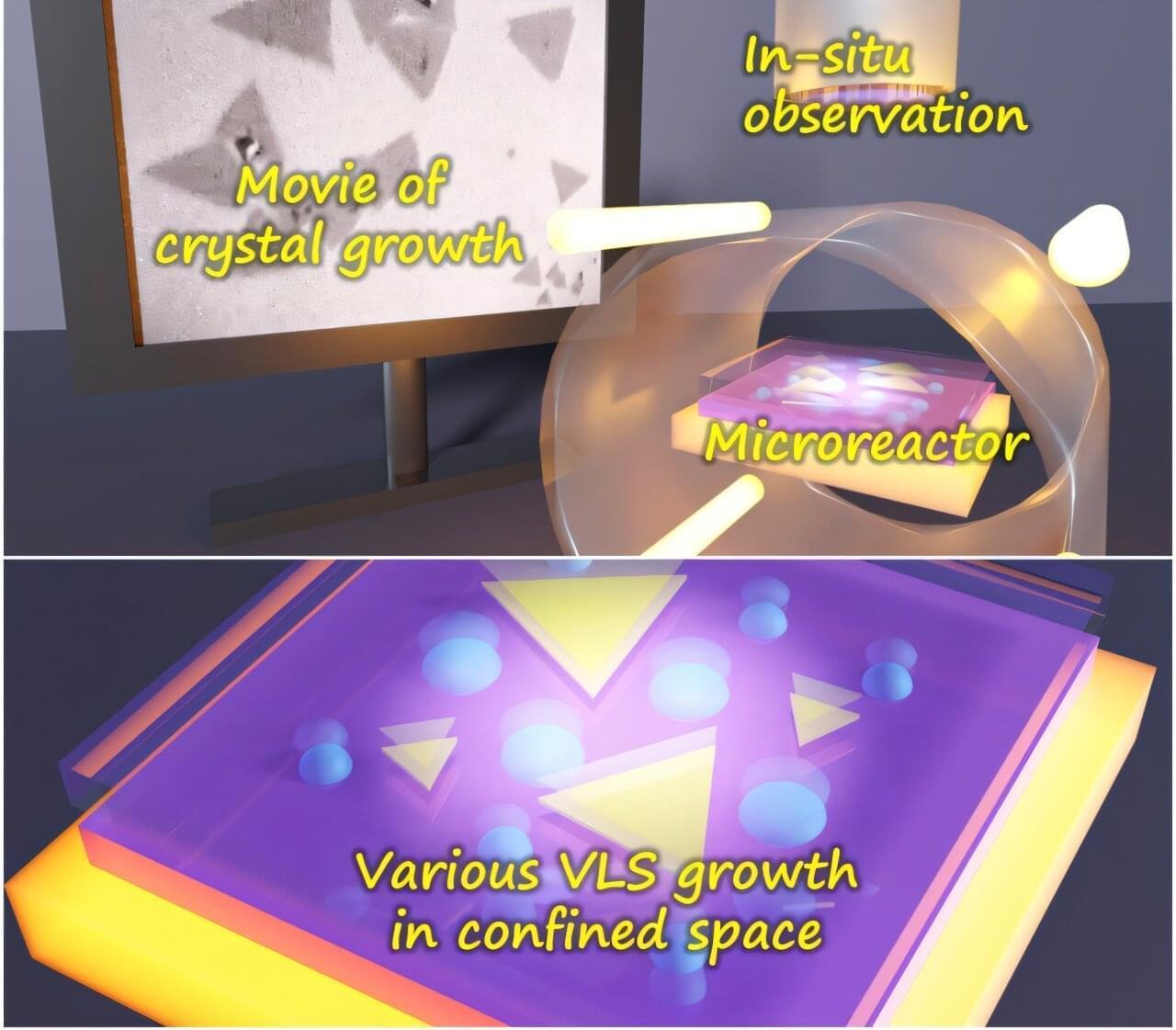

A research team led by Research Associate Professor Hiroo Suzuki from the Department of Electrical and Communication Engineering at Okayama University, Japan, together with Dr. Kaoru Hisama from Shinshu University and Dr. Shun Fujii from Keio University, has now overcome a key barrier by directly observing how these materials grow at the atomic scale. Using an advanced in situ observation system, the researchers captured real-time images of monolayer transition metal dichalcogenides (TMDCs) forming inside a micro-confined reaction space. The study was published on December 12, 2025, in the journal Advanced Science.

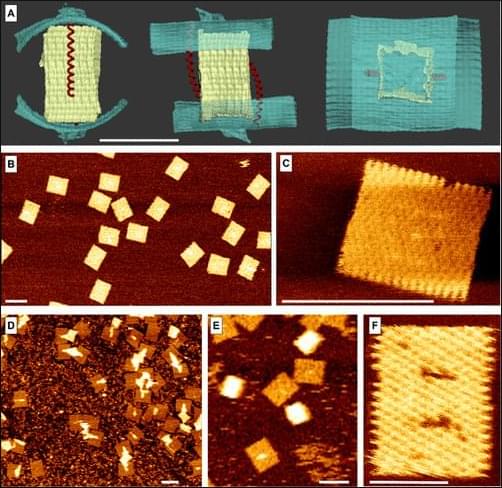

The work builds on earlier success by the team in synthesizing large-area monolayer TMDC single crystals using a substrate-stacked microreactor. While that method consistently produced high-quality materials, the mechanisms governing crystal growth inside the confined space were poorly understood.