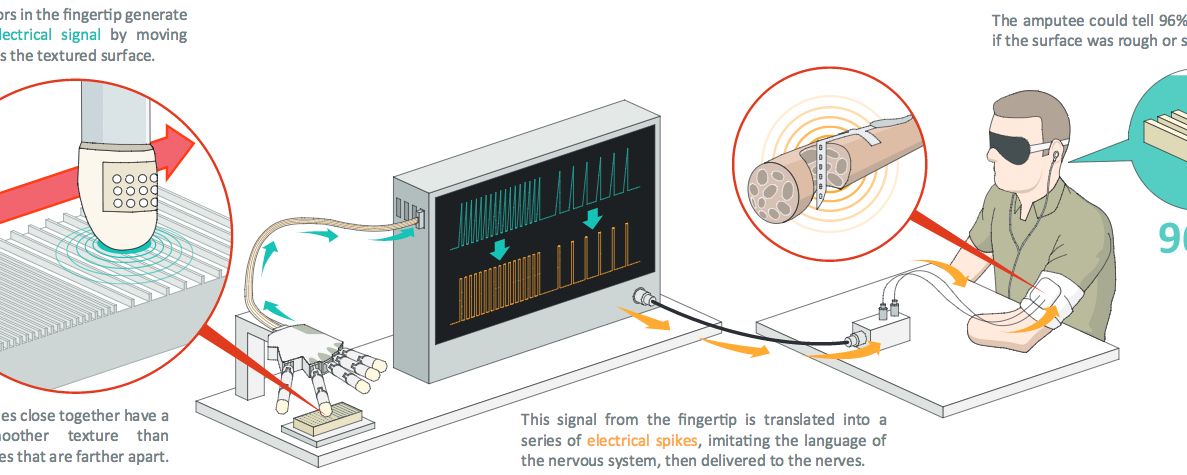

Making the most of the low light in the muddy rivers where it swims, the elephant nose fish survives by being able to spot predators amongst the muck with a uniquely shaped retina, the part of the eye that captures light. In a new study, researchers looked to the fish’s retinal structure to inform the design of a contact lens that can adjust its focus.

Imagine a contact lens that autofocuses within milliseconds. That could be life-changing for people with presbyopia, a stiffening of the eye’s lens that makes it difficult to focus on close objects. Presbyopia affects more than 1 billion people worldwide, half of whom do not have adequate correction, said the project’s leader, Hongrui Jiang, Ph.D., of the University of Wisconsin, Madison. And while glasses, conventional contact lenses and surgery provide some improvement, these options all involve the loss of contrast and sensitivity, as well as difficulty with night vision. Jiang’s idea is to design contacts that continuously adjust in concert with one’s own cornea and lens to recapture a person’s youthful vision.

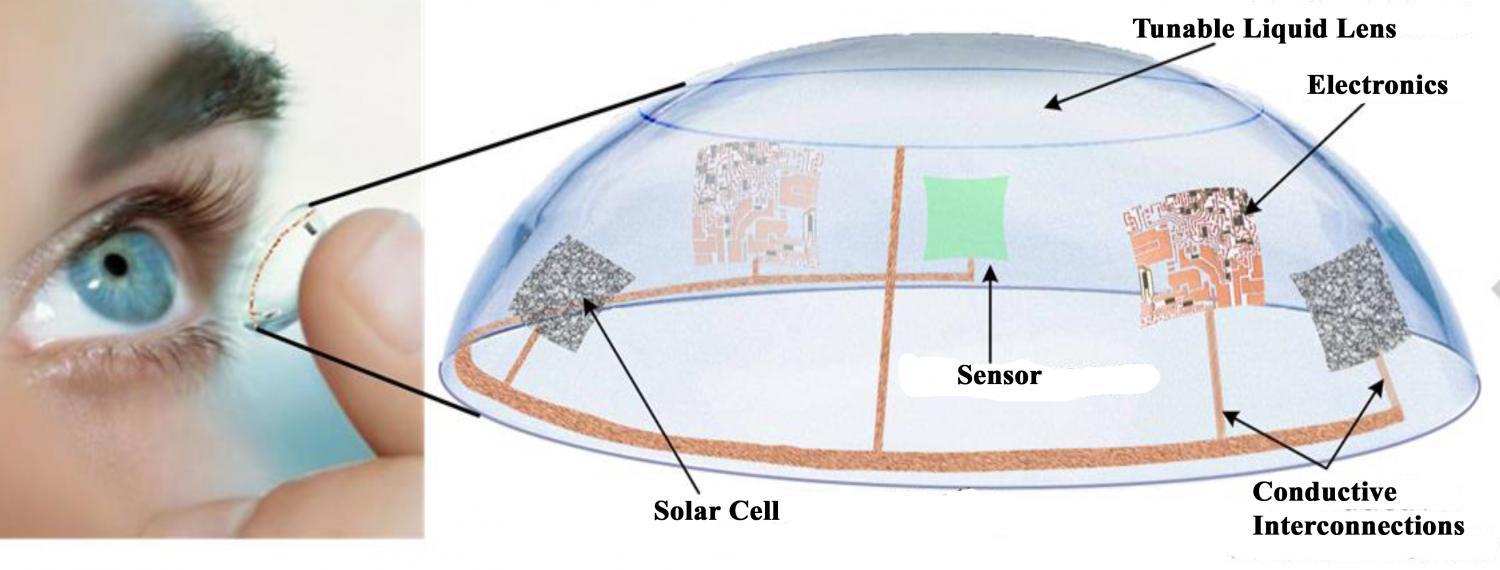

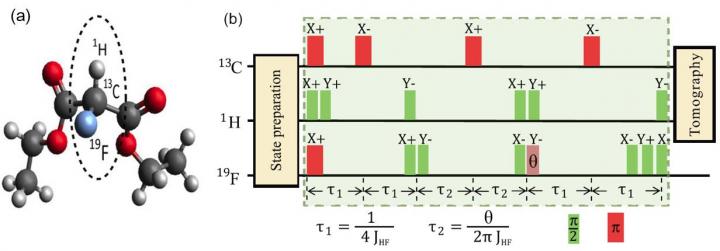

The project, for which Jiang received a 2011 NIH Director’s New Innovator Award (an initiative of the NIH Common Fund) funded by the National Eye Institute, requires overcoming several engineering challenges. They include designing the lens, algorithm-driven sensors, and miniature electronic circuits that adjust the shape of the lens, plus creating a power source — all embedded within a soft, flexible material that fits over the eye.