The startup uses 3D-printing techniques to assemble a human heart, one heart-cell layer at a time.

Last year, I got invited to a super-deluxe private resort to deliver a keynote speech to what I assumed would be a hundred or so investment bankers. It was by far the largest fee I had ever been offered for a talk — about half my annual professor’s salary — all to deliver some insight on the subject of “the future of technology.”

I’ve never liked talking about the future. The Q&A sessions always end up more like parlor games, where I’m asked to opine on the latest technology buzzwords as if they were ticker symbols for potential investments: blockchain, 3D printing, CRISPR. The audiences are rarely interested in learning about these technologies or their potential impacts beyond the binary choice of whether or not to invest in them. But money talks, so I took the gig.

After I arrived, I was ushered into what I thought was the green room. But instead of being wired with a microphone or taken to a stage, I just sat there at a plain round table as my audience was brought to me: five super-wealthy guys — yes, all men — from the upper echelon of the hedge fund world. After a bit of small talk, I realized they had no interest in the information I had prepared about the future of technology. They had come with questions of their own.

The next phase of a NASA sponsored mission to 3D print human organs and tissues in space will launch in February 2019. A 3D BioFabrication Facility (BFF) developed by nScrypt and Techshot and destined for the International Space Station (ISS) will form part of the cargo of SpaceX CRS-17.

3D printing in zero gravity

nScrypt is based in Orlando, Florida and is a manufacturer of industrial micro-dispensing and 3D printing systems. The company is spin out of Sciperio Inc who, under a DARPA contact, developed an award winning bioprinter in 2003.

For: Moon Village Association Location: EU, initiated on workshop at ISU in Strasbourg, then created in Prague, Lund, Terracina, London Year of Completion: 2018 Team: space architects Tomas Rousek, Katarina Eriksson, Vittorio Rossetti.

It was very inspiring to see a presentation of Prof. Jan Woerner, ESA director general, at the MVA workshop at ISU in Starsbourg. When we have seen the range of all elements that are encompassed in the vision, it was clear to us that it would be good to illustrate it with more than just one 3D-printed module. With colleagues space architects Katarina Eriksson and Vittorio Rossetti we offered our help to MVA organizers to illustrate the new vision of Global Moon Village. We created 3D concept including more the components of lunar exploration and infrastructure that were mentioned, i.e. modules of ESA, NASA and international and commercial partners, Google Lunar X-Prize rovers and cis-lunar station.

We also proposed facelift concept of logo for MVA, with half moon over O circle.

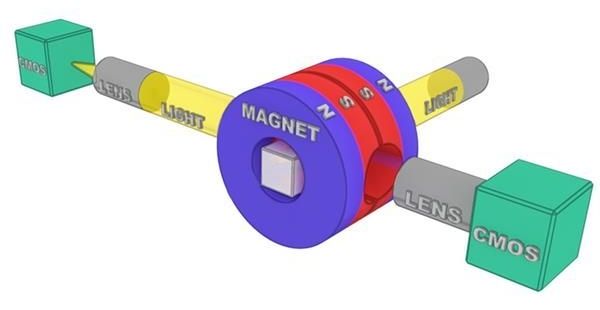

3D bioprinting is a process for patterning and assembling complex functional living architectures in a gradient fashion. Generally, 3D bioprinting utilizes the layer-by-layer method to deposit materials known as bioinks to create tissue-like structures. Several 3D bioprinting techniques have been developed over the last decade, for example, magnetic bioprinting, a method that employs biocompatible magnetic nanoparticles to print cells into 3D structures.

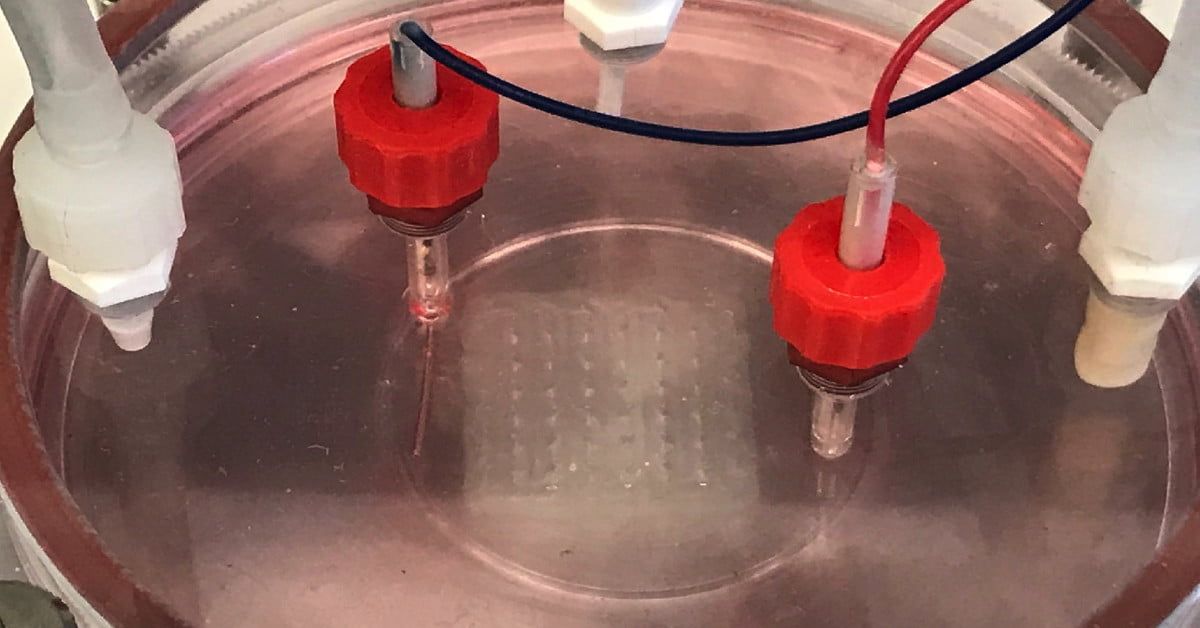

But now a Russian research team has developed a new method of bioprinting that allows to create 3D biological objects without the use of layer-by-layer approach and magnetic labels. The new method, which involves magnetic levitation research in conditions of microgravity, was conducted by the 3D Bioprinting Solutions company in collaboration with other Russian and foreign scientists, including the Joint Institute for High Temperatures of the Russian Academy of Sciences (JIHT RAS).

ELON MUSK wants to plump humans on Mars by 2024 and the first batch of settlers could live in 3D-printed home pods that pack hologram computers.

You’ll be able to tour the Red Planet habitat in virtual reality and view a scale model of the sci-fi living space at the Goodwood Festival of Speed next month.

Ever wish you could visit other planets in our solar system without launching on a deep-space mission? Now you can embark on an interplanetary adventure right from the palm of your hand, thanks to gorgeous, 3D-printed planet models and an augmented-reality (AR) app.

Brought to you by AstroReality, the same company that created the “Lunar” AR moon model and its new Earth counterpart, this set includes miniature models of all eight planets and one model of the dwarf planet Pluto. Each model is 1.2 inches (3 centimeters) in diameter and color-printed with a resolution of 0.1 millimeter per pixel.

Without the AR app, you can admire detailed features such as Pluto’s “heart” and Jupiter’s Great Red Spot. But the real extraterrestrial adventure begins when you open the AstroReality app (available for iOS and Android) on your mobile device and point the camera at any of the nine models. [Our Solar System: A Photo Tour of the Planets].

At MBC Biolabs, an incubator for biotech startups in San Francisco’s Dogpatch neighborhood, a team of scientists and interns working for the small startup Prellis Biologics have just taken a big step on the path toward developing viable 3D-printed organs for humans.

The company, which was founded in 2016 by research scientists Melanie Matheu and Noelle Mullin, staked its future (and a small $3 million investment) on a new technology to manufacture capillaries, the one-cell-thick blood vessels that are the pathways which oxygen and nutrients move through to nourish tissues in the body.

Without functioning capillary structures, it is impossible to make organs, according to Matheu. They’re the most vital piece of the puzzle in the quest to print viable hearts, livers, kidneys and lungs, she said.

Within 4–5 years Made In Space believes their Archinaut space manufacturing robot and manufacturing mini factory will be making large structures like trusses and reflectors in space.

The Archinaut has an industrial-sized 3D printer, cartridges full of plastics and alloys, and robotic arms programmed to assemble the big items extruded by the printer without any human supervision. All Archinaut parts are able to survive in microgravity and harsh conditions like lunar dust storms and extreme temperatures.