In the 1980s when micro-electro-mechanical systems (MEMS) were first created, computer engineers were excited by the idea that these new devices that combine electrical and mechanical components at the microscale could be used to build miniature robots.

The idea of shrinking robotic mechanisms to such tiny sizes was particularly exciting given the potential to achieve exceptional performance in metrics such as speed and precision by leveraging a robot’s smaller size and mass. But making robots at smaller scales is easier said than done due to limitations in microscale 3D manufacturing.

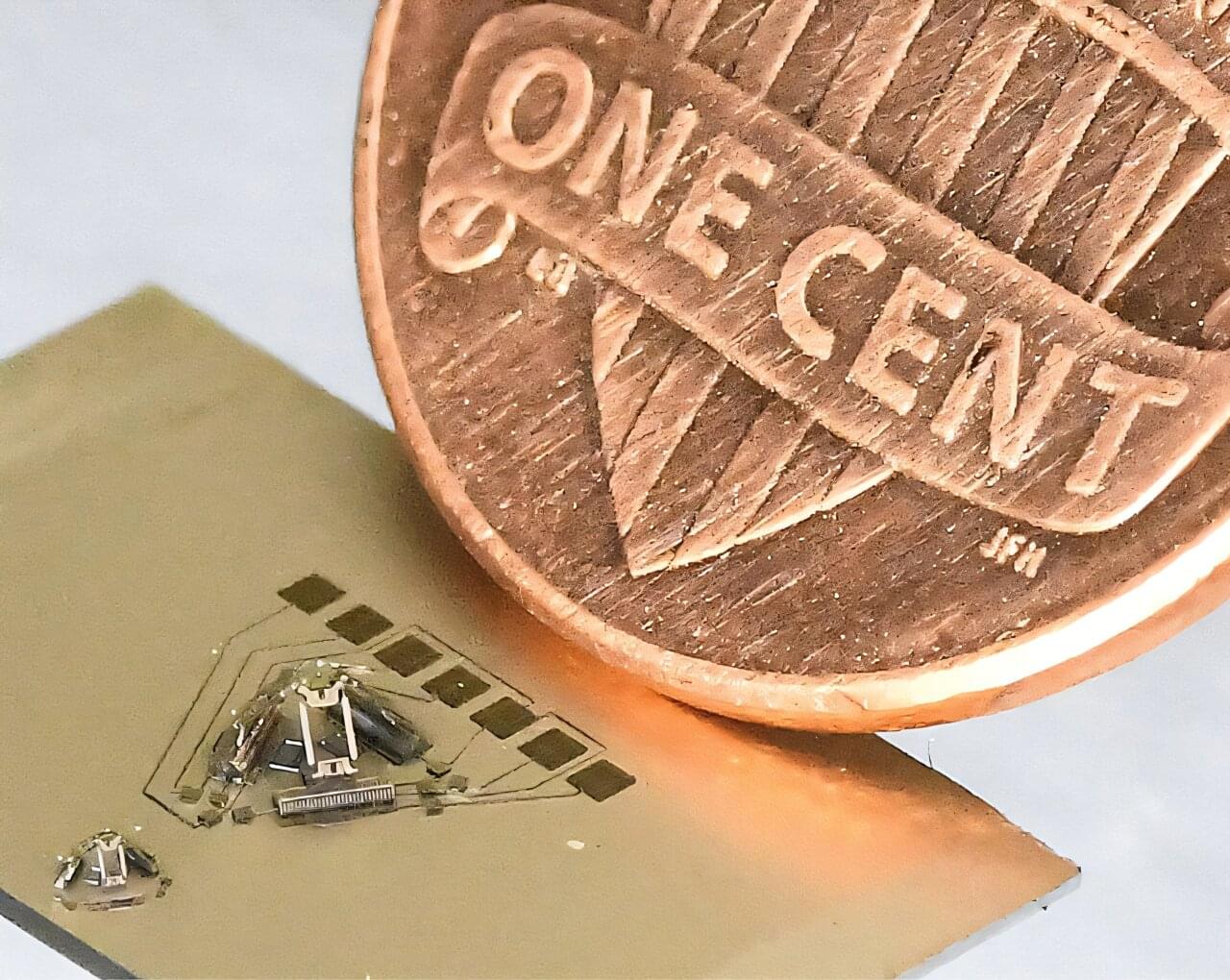

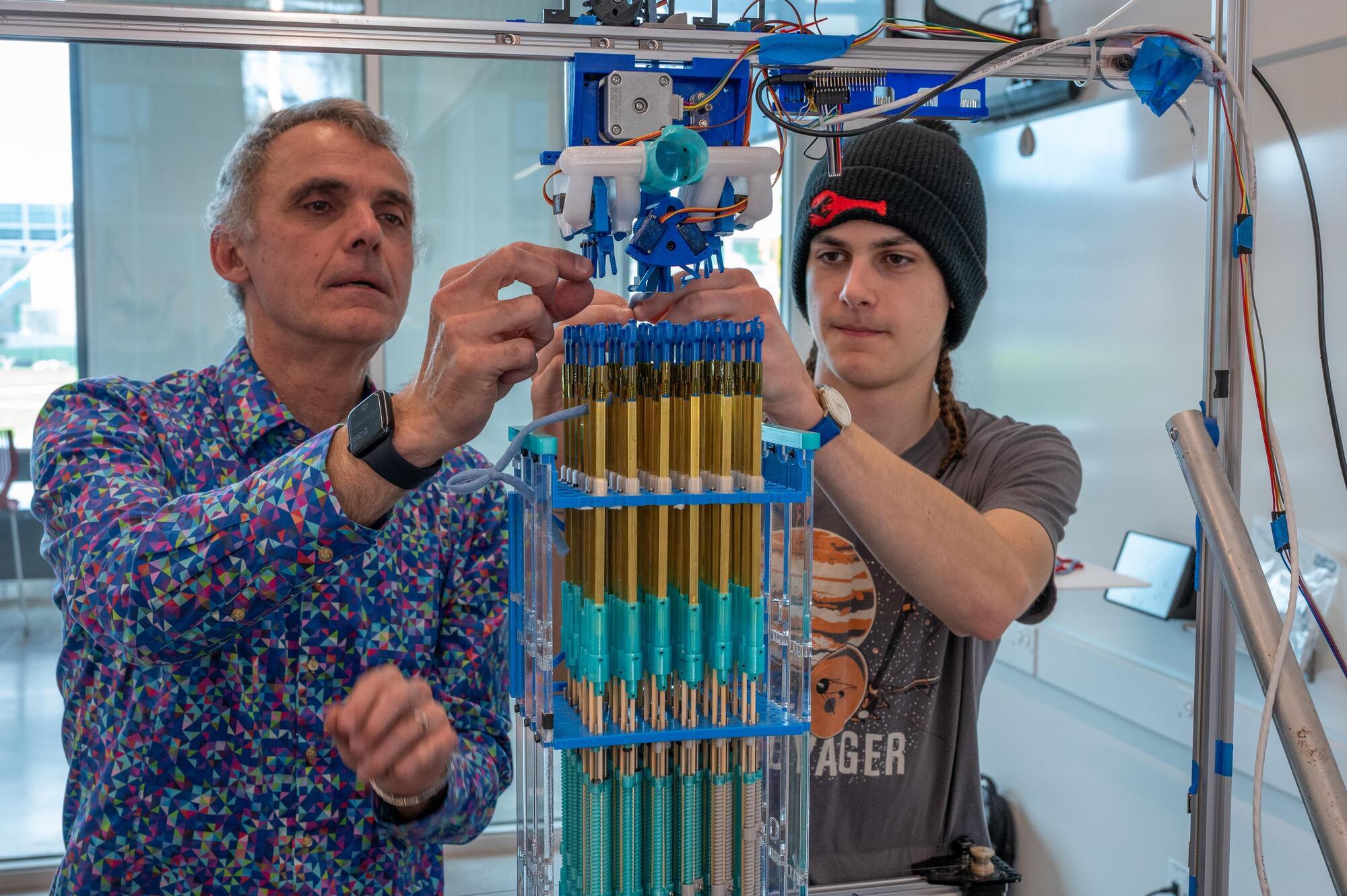

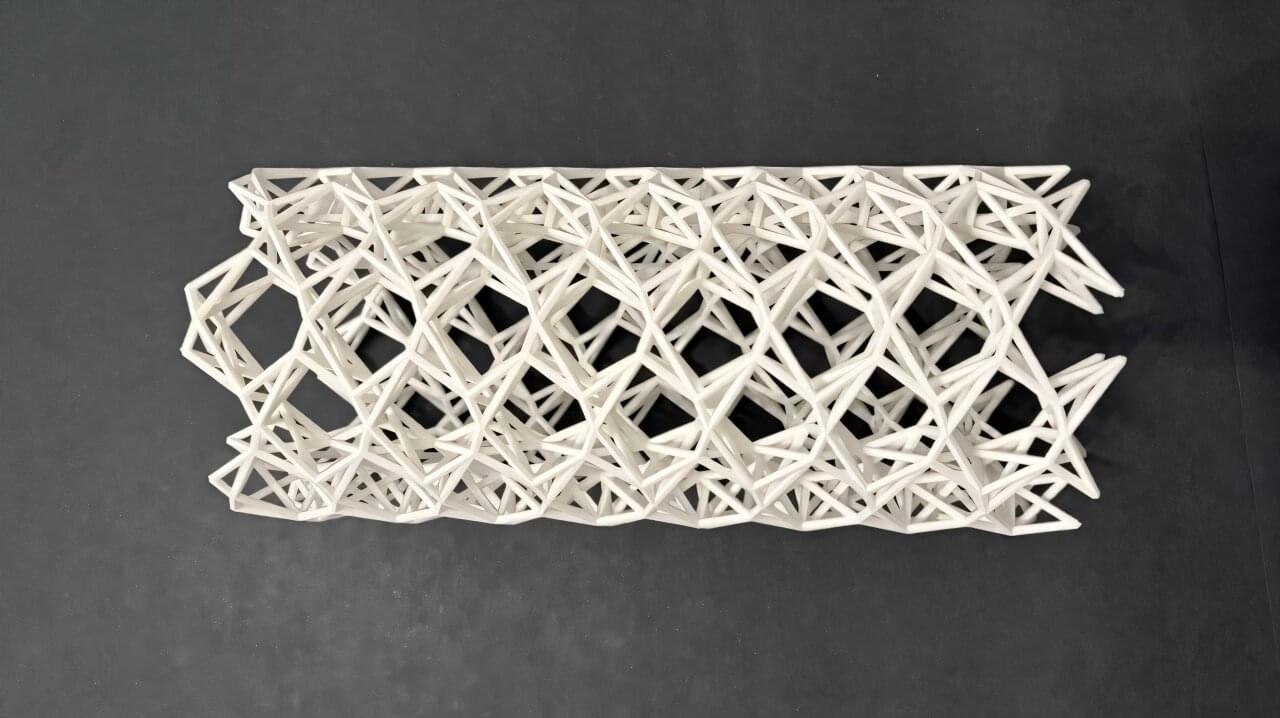

Nearly 50 years later, Ph.D. students Steven Man and Sukjun Kim, working with Mechanical Engineering Professor Sarah Bergbreiter, have developed a 3D printing process to build tiny Delta robots called microDeltas. Delta robots at larger scales (typically two to four feet in height) are used for picking, placing, and sorting tasks in manufacturing, packaging, and electronics assembly. The much smaller microDeltas have the potential for real-world applications in micromanipulation, micro assembly, minimally invasive surgeries, and wearable haptic devices.