My new article for Vice Motherboard on extreme biohacking that compares the Uncanny Valley to Speciation Syndrome:

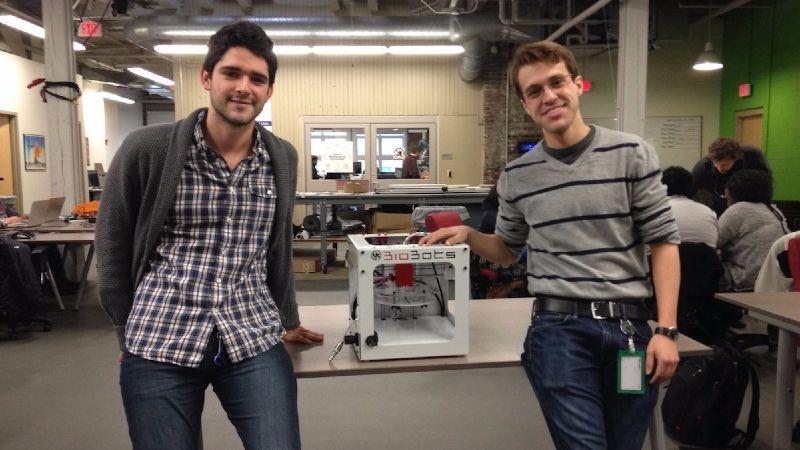

Transhumanism tech like CRISPR, 3D printing, and coming biological regeneration of limbs will not only change lives for those that have deformities, but it will change how we look at things like a person with a three-foot tail and maybe even a second head.

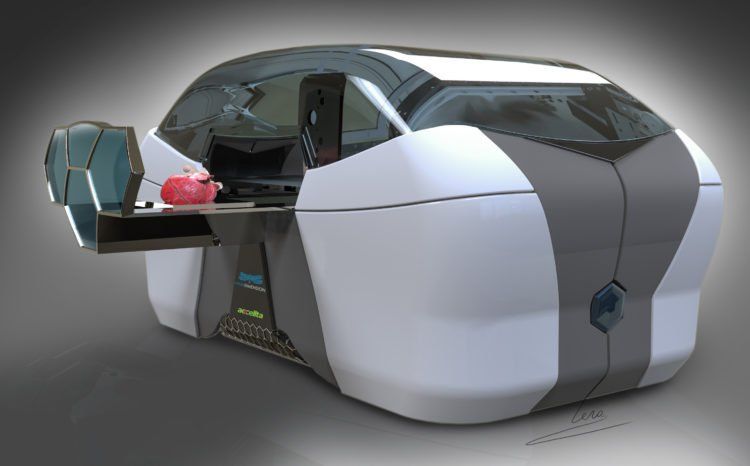

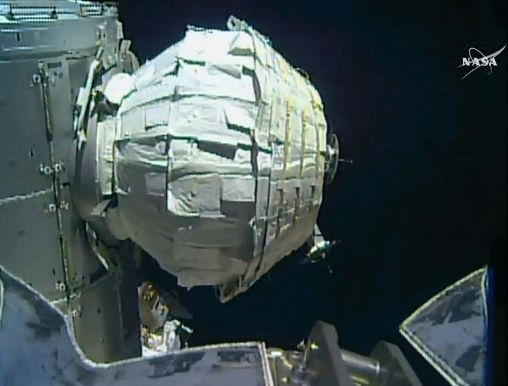

At the core of all this is the ingrained belief that the human being is pre-formed organism, complete with one head, four limbs, and other standard anatomical parts. But in the transhumanist age, the human being should be looked at more like a machine—like a car, if you will: something that comes out a particular way with certain attributes, but then can be heavily modified. In fact, it can be rebuilt from scratch.

In the future, there may even be walk-in clinics where people can go to have various gene treatments done to affect their bodies. Already, we have IVF centers where people can use radical tech to privately get pregnant—and also control and monitor various stages of a child’s birth. Eventually, if government allows it, gene editing centers will also offer a multitude of designer baby traits, some which also would come via CRISPR. We might even eventually use artificial wombs for the whole process.

Economically, a trillion dollar industry could be created by the burgeoning genetic editing industry—one that greatly benefits human health and science innovation. But of course, first we must get over our fears of modifying the human body and the effects of speciation syndrome.