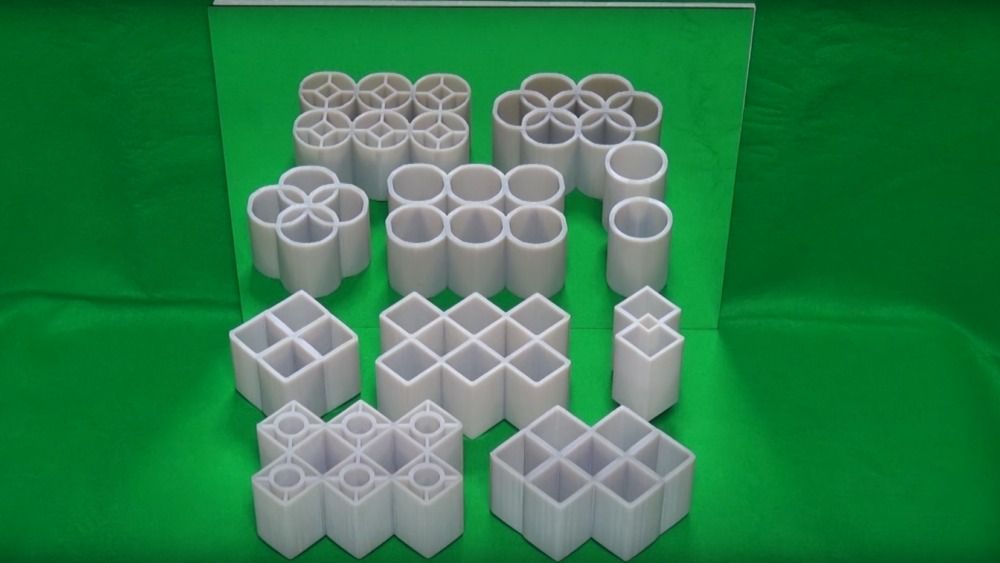

California’s space technology company Made In Space, currently preparing their second zero gravity 3D printer called the Additive Manufacturing Facility for the International Space Station, will be playing a key role in a NASA project that could completely revolutionize manufacturing in space. They will be partnering with Northrop Grumman and Oceaneering Space Systems on Archinaut, a 3D printer capable of working in the vacuum of space that will be equipped with a robotic arm. Archinaut is scheduled to be installed on an external space station pod and will be capable of in-orbit additive manufacturing, the fabrication and assembly of communications satellite reflectors or the repair on in-orbit structures and machinery.