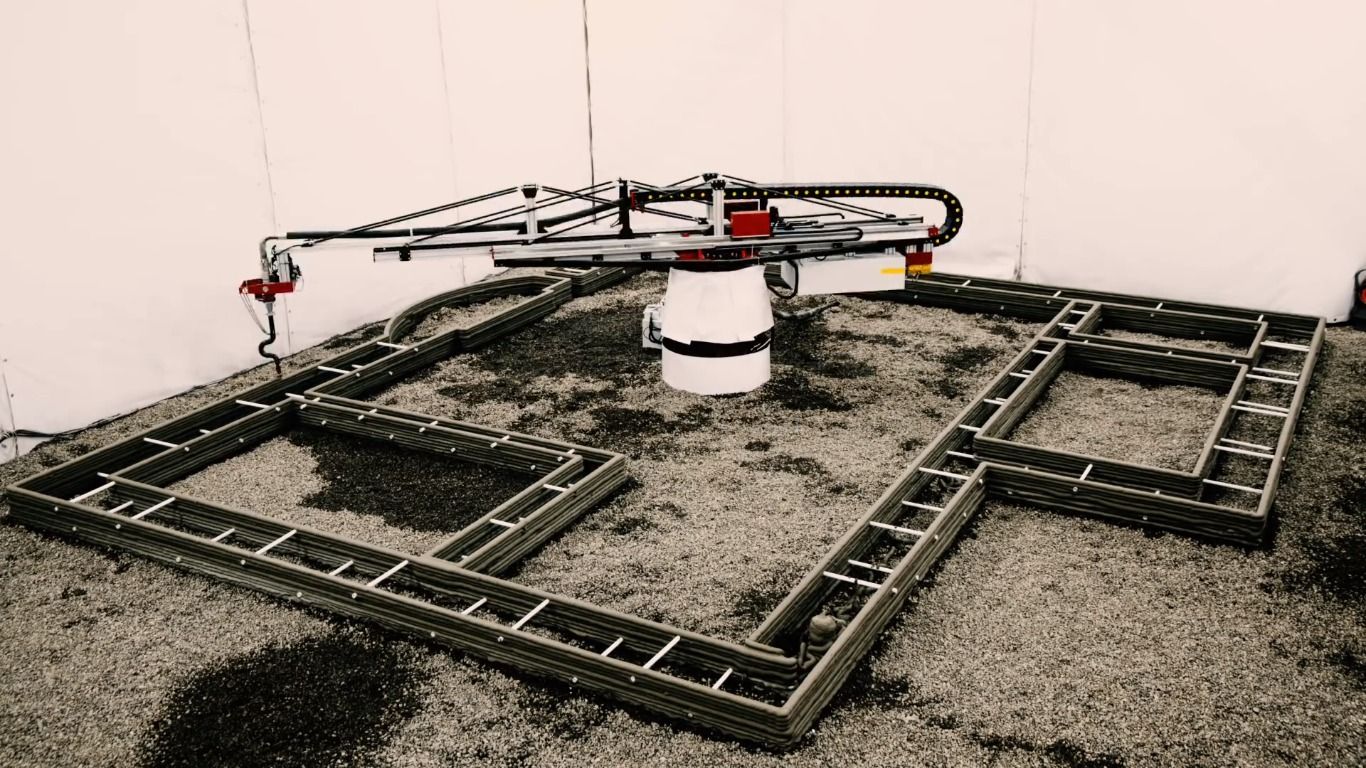

NESS ZIONA, Israel, December 12, 2016 – Nano Dimension Ltd., a leader in the field of 3D Printed Electronics (NASDAQ, TASE: NNDM), will showcase its 3D printer for professional printed circuit boards (PCBs) and electric circuits in Eureka Park during CES 2017. The technology sits firmly at the intersection of 3D printing and printed electronics, and sets new standards for accuracy, complexity and multi-materiality in the fields of 3D printing and electronics prototyping.