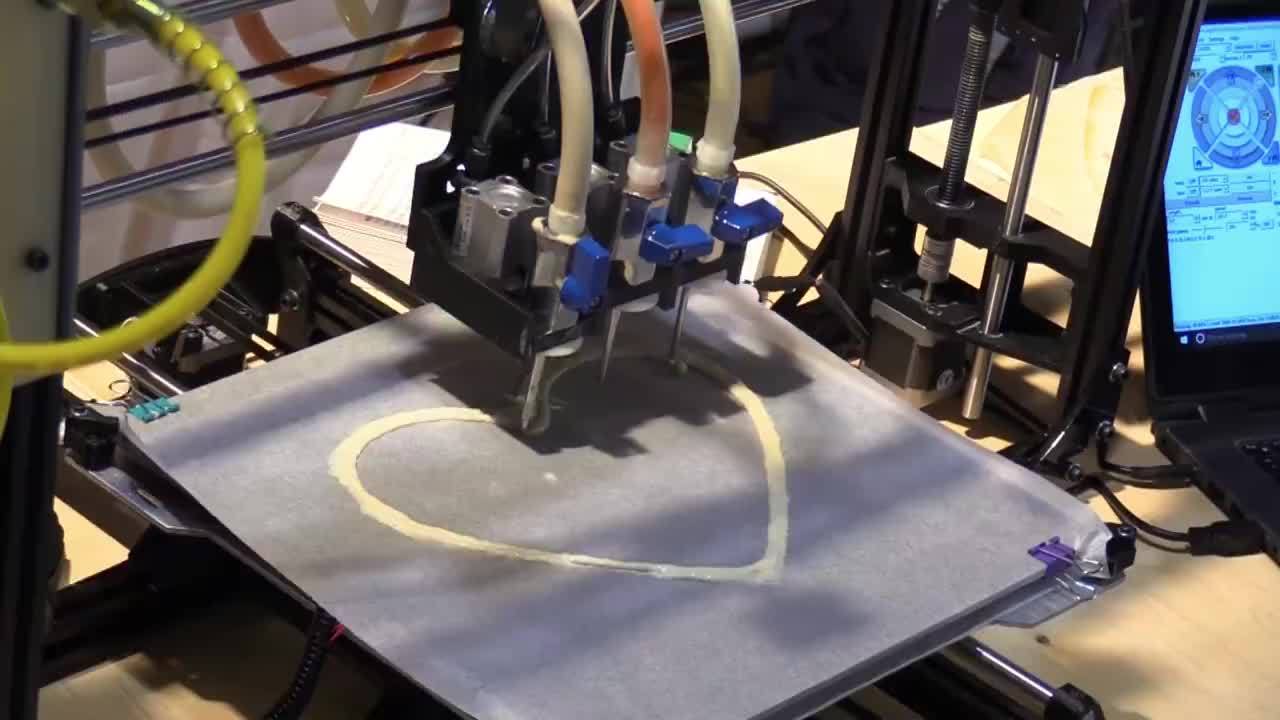

Click on photo to start video.

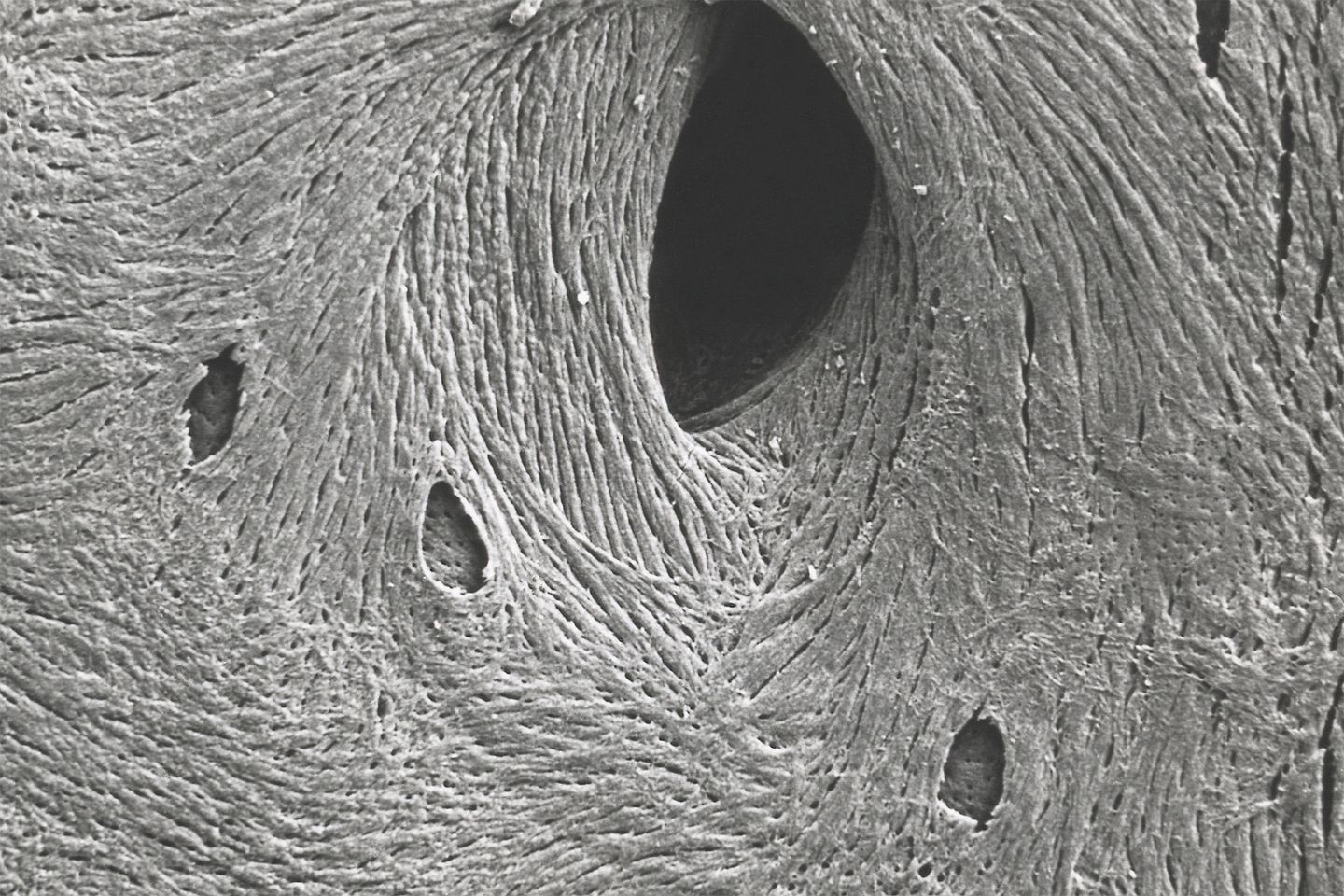

A team from the Universities of Glasgow, Strathclyde, the West of Scotland and Galway have created a device that sends nano vibrations across mesenchymal stem cells suspended in a collagen gel.

The authors of the paper, published in the Nature Biomedical Engineering journal, found that these tiny vibrations turn the cells into a 3D model of mineralised bone ‘putty’. This putty isn’t quite as hard as bone at this stage. That’s where the body comes in.

“We add the bone putty to an anatomically correct, rigid living scaffold, that we made by 3D printing collagen,” says Matthew Dalby, professor of cell engineering at the University of Glasgow, and one of the lead authors of the paper. “We put lots of cells in the body so it has a chance to integrate this new bone. We tell the cells what to do in the lab, then the body can act as a bioreactor to do the rest.”

Scientists have grown living bone in the lab by sending vibrations through stem cells. It could help amputees and people with osteoporosis.

Cellulose is the most abundant organic polymer in the world. It is the primary compound in the cell walls of green plants, and is typically used to make paper and cardboard.

At the VTT Technical Centre of Finland, a state owned research and development non-profit, scientists have used nano-structured cellulose to make a 3D printable material.

The nanocellulose paste is now in development to make smart-dressings that heal and monitor skin wounds.

(3Ders.org) The rapid advance of 3D printing technology means that hybrid-material wind turbine blades complete with metal mesh inserts are no longer the stuff of imagination. These energy savers with “sci-fi-level” performance could become reality in as soon as two years. Philip Totaro of Totaro & Associates, “The greatest challenge for wind turbine blade structural and manufacturing engineers is to implement the idealized performance and noise mitigated designs of aerodynamics engineers,” explains Totaro. “Limitations of previous generations of manufacturing technology and the reliance on lower cost materials have limited the type of spar/shear web structures which could be utilized.” But 3D printing could be about to change all that, Totaro says.

For millennials and the generations to follow, the future will differ radically from their parents’ world. Massively powerful digital technologies will bring seismic changes in the lifestyles, opportunities, privileges and choices experienced by young people compared to their parents.

The ‘singularity’ event that scientists talk about in artificial intelligence (AI) — when robots would outsmart human beings in reasoning — has just been moved up, according to a top scientist at HP Inc. The progress in AI and machine learning has been so rapid that scientists have upped the estimate for the ‘singularity’ to happen in 2029 from 2040, shaving off 11 years of development time, says Shane Wall, Chief Technology Officer at HP, who also heads the HP Labs which is at the centre of innovation within the company.

Wall, who was speaking at the HP Reinvent Partner Forum here, said there may be some who watch with fear for that event to happen but taken adequate precautions, this change would bring in much good for everyone — be it in manufacturing, health, innovation or elsewhere. He said AI handles huge amount of data and can discern patterns to take decisions. “Machine learning uses AI and big data to learn and it can find things that no humans can see,” Wall noted.

According to him, already there are massive data farms which are crunching big numbers and there are research labs and companies where machines are taught how to use data to managing things around us. Wall, who joined HP over a decade ago, drives the company’s technology vision and its strategy and helms the innovation community within. According to him, machines have become smart enough to predict failures within a system and 3D manufacturing is a massive revolution in the making. “Already, 3D printing is handling intricate products and in the future this will bring about a disruptive change,” Wall said.

What will 3D printers ultimately evolve into? No one has a functioning crystal ball in front of them I assume, but a good guess would be a machine which can practically build anything its user desire, all on the molecular, and eventually atomic levels. Sure we are likely multiple decades away from widespread molecular manufacturing, but a group of chemists led by medical doctor Martin D. Burke at the University of Illinois may have already taken a major step in that direction.

Burke, who joined the Department of Chemistry at the university in 2005, heads up Burke Laboratories where he studies and synthesizes small molecules with protein-like structures. For those of you who are not chemists, small molecules are organic compounds with very low molecular weight of less than 900 daltons. They usually help regulate biological processes and make up most of the drugs we put into our bodies, along with pesticides used by farmers and electronic components like LEDs and solar cells.

At a test facility in rural Illinois, engineers fabricate structural segments for buildings. But instead of using typical assembly techniques, here at this dirt-floor arena with tightly controlled conditions, teams employ robotic nozzles to extrude domes, beams and cylinders using material chosen for its similarity to the regolith found on the surface of the planet Mars.

The activity comprises part of the 3D-Printed Mars Habitat Design Challenge, which focuses on how to go about building structures on Mars to eventually house human explorers. It’s a component of the NASA Centennial Challenges, a contest series that solicits the public to solve the practical problems of future space exploration. The third phase of the challenge, underway now, focuses on creating stable structural members using an additive manufacturing process based on basaltic rock geologically similar to what is found on Mars.

“This leg of the competition is focused on the materials, specifically the indigenous Mars regolith,” explains Tony Kim, deputy program manager for NASA’s Centennial Challenge. “All of the teams are approaching it differently.” Previous phases of the challenge focused on conceptual designs for habitats and proof-of-concept 3D-printed shapes. But this showdown emphasizes pure structural strength, as the 3D-printed cylinders, beams and domes will be subjected to loading until they fail.