Nature has an extraordinary knack for producing composite materials that are simultaneously light and strong, porous and rigid — like mollusk shells or bone. But producing such materials in a lab or factory — particularly using environmentally friendly materials and processes — is extremely challenging.

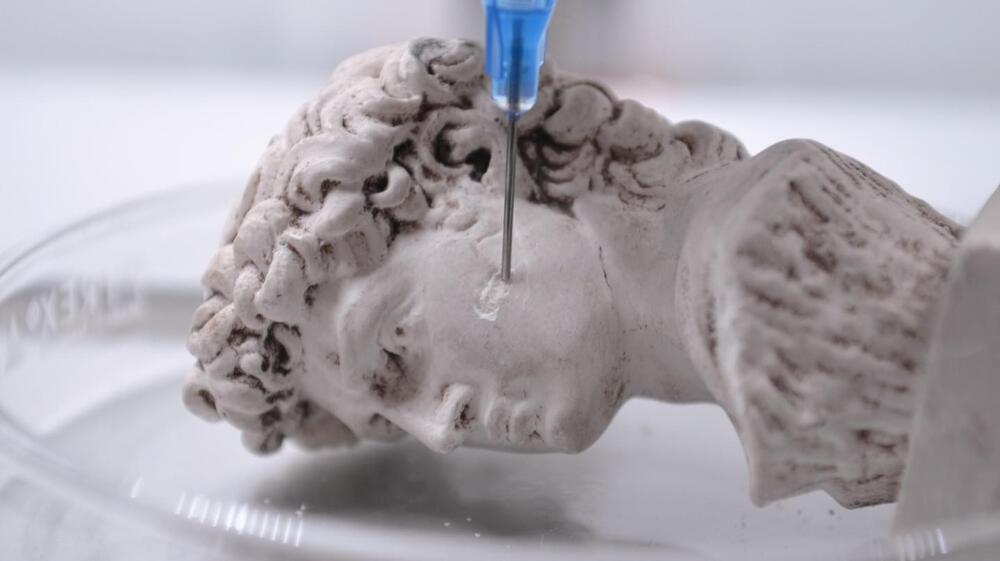

Researchers in the Soft Materials Laboratory in the School of Engineering turned to nature for a solution. They have pioneered a 3D printable ink that contains Sporosarcina pasteurii: a bacterium which, when exposed to a urea-containing solution, triggers a mineralization process that produces calcium carbonate (CaCO3). The upshot is that the researchers can use their ink — dubbed BactoInk — to 3D-print virtually any shape, which will then gradually mineralize over the course of a few days.

-This would be good for coral reefs.

EPFL researchers have published a method for 3D-printing an ink that contains calcium carbonate-producing bacteria. The 3D-printed mineralized bio-composite is unprecedently strong, light, and environmentally friendly, with a range of applications from art to biomedicine.